What labels should I buy?

Leave a CommentWhat labels should I buy?

Glass Bottles:

Film Labels:

Sometimes it may be hard to decide what labels you should buy. When it comes to deciding what labels work best for your bottling needs you need to first look at what the bottle is made of. If you are looking for glass bottle labels you have two options to choose from. You could go with a film label or a paper label. For film labels we generally use hot melt adhesives. We work with a variety of manufacturers to provide a full line of pressure sensitive labeling adhesives for this application.

Hot Melt Options:

We have a robust adhesive that has a very strong adhesion to glass and PET bottles. We generally use this adhesive for basic labeling applications such as bottled water or non carbonated beverages.

We also offer a different pressure sensitive adhesive that provides superior performance for high speed labeling on labeling equipment. This would have good heat resistance, clean machining, and high-residual tack. It also offers excellent adhesion to poly bottles and labels. This product sprays well, and is optimal for PatternJet® or similar application systems.

Our last option we recommend is a colorless, full pressure sensitive labeling adhesive that is formulated to machine well on rotary labelers. This powerful adhesive remains robust in both hot and cold end-use environments, making it suitable for a variety of applications.

Paper Labels:

If you are using paper labels for your glass applications then you can choose from water-based or hot melt adhesives. It’s hard for us to say which you should be using without looking at your line. We’re happy to give you a free line audit to help you figure out what adhesives you should be using. Just contact us!

Water-Based Options:

For paper labels we have several options. We have a non-casein adhesive that is specifically developed for glass bottle labeling. It offers high wet tack that performs well on cold, wet glass bottles. It has a fast set speed, and is very easy to clean up.

Another option we have provides high adhesion to PET and heavily-coated glass, treated PE and PP. It has excellent cold crack resistance and very fast set speed reduces or eliminates label flagging and swimming. It delivers superior clean-ability compared to most other premium adhesives on the market.

We also have a highly versatile non-casein adhesive that performs well on coated and non-coated labels at a wide range of operating speeds. It offers high tack, fast set speed and clean machining for more efficient operation. It also offers unparalleled ice resistance and is available in different viscosity ranges.

Hot Melt Options:

Other than water-based options we also have some hot melts that work well too. We supply a full-pressure sensitive labeling adhesive that is a robust adhesive with excellent adhesion to glass and PET bottles. This adhesive is ideal for basic labeling applications such as bottled water but is not recommended for carbonated beverages.

We also have another full-pressure-sensitive adhesive that provides superior performance for high-speed labeling on labeling equipment. With good heat resistance, clean machining and high-residual tack, it offers excellent adhesion to poly bottles and labels. This product sprays extremely well and is optimal for PatternJet® or similar application systems.

Our last hot melt that we recommend for paper labels is a colorless, full-pressure sensitive labeling adhesive that is formulated to machine well on rotary labelers. This powerful adhesive remains robust in both hot and cold end-use environments, making it suitable for a variety of application processes.

Metal Containers:

Film Labels:

When working with metal containers there are two film labels that we recommend. They are two different hot melts.

Hot Melt Options:

We have a full-pressure-sensitive adhesive that provides superior performance for high-speed labeling on labeling equipment. With good heat resistance, clean machining and high-residual tack, it offers excellent adhesion to poly bottles and labels. This product sprays extremely well and is optimal for PatternJet® or similar application systems.

Another option we have is a full-pressure sensitive labeling adhesive is a robust adhesive with excellent adhesion to glass and PET bottles. This adhesive is ideal for basic labeling applications such as bottled water but is not recommended for carbonated beverages.

We do not recommend using any water-based adhesives for metal containers.

Paper Labels:

For Paper labels we offer three different hot melts.

Hot Melt Options:

We use one which is the industry standard in roll-through labeling, this hot-melt non-permanent adhesive is designed for convenient, easy use. With an aggressive tack, it offers excellent, reliable label pick up.

We also have a roll-through labeling product offers the same high performance, but is formulated with a different raw material slate for optimal supply security. This non-permanent product offers excellent hot tack and good thermal stability for open pot applications.

Our last hot melt option is a permanent adhesion pick up for roll-through labeling applications. It has high tack properties ensuring optimal performance for high-speed applications. Because it machines cleanly, this hot-melt adhesive is ideal for swirl spray label application as well.

PET Bottles:

Film Labels:

We have four different film labels that we recommend using for PET bottles. They are all hot melts.

Hot Melt Options:

The first options is our highest performing semi-pressure sensitive labeling adhesive. It is ideal for carbonated beverage bottles. The combination of low-melt viscosity and high cohesive strength ensures complete wet-out on the label while eliminating flagging during the filling process.

The second option we recommend is a full-pressure sensitive labeling adhesive. It is a robust adhesive with excellent adhesion to glass and PET bottles. This adhesive is ideal for basic labeling applications such as bottled water but is not recommended for carbonated beverages.

The third option is a full-pressure-sensitive adhesive that provides superior performance for high-speed labeling on labeling equipment. With good heat resistance, clean machining and high-residual tack, it offers excellent adhesion to poly bottles and labels. This product sprays extremely well and is optimal for PatternJet® or similar application systems.

The fourth option is a colorless, full-pressure sensitive labeling adhesive is formulated to machine well on rotary labelers. This powerful adhesive remains robust in both hot and cold end-use environments, making it suitable for a variety of application processes.

Paper Labels:

For paper labels we offer 3 different hot melts and 3 different water-based adhesives that can be suitable for your application.

Water-Based Options:

The first water-based option we offers fast set and excellent adhesion to PET bottles. Due to its low viscosity, semi-psa is ideal for rotary applications at medium to high speeds.

The second water-based option has excellent tack and clean machining. It provides high adhesion to PET and heavily-coated glass, treated PE and PP. Its excellent cold crack resistance and very fast set speed reduces or eliminates label flagging and swimming. It delivers superior clean-ability compared to most other premium adhesives on the market.

The third water-based option we have is an excellent choice for PET. It’s a water-based adhesive that provides consistently clean machining and machine stability with a medium open time. This product has a medium tack and is best suited for rotary applications at medium speeds.

Hot Melt Options:

The first hot melt that we recommend is a full-pressure sensitive labeling adhesive that is a robust adhesive with excellent adhesion to glass and PET bottles. This adhesive is ideal for basic labeling applications such as bottled water but is not recommended for carbonated beverages.

The second one that we recommend is a full-pressure-sensitive adhesive provides superior performance for high-speed labeling on labeling equipment. With good heat resistance, clean machining and high-residual tack, it offers excellent adhesion to poly bottles and labels. This product sprays extremely well and is optimal for PatternJet® or similar application systems.

The third we recommend is a colorless, full-pressure sensitive labeling adhesive is formulated to machine well on rotary labelers. This powerful adhesive remains robust in both hot and cold end-use environments, making it suitable for a variety of application processes.

Polyolefin Bottles:

Film Labels:

We offer 2 hot melt adhesives for film labels.

Hot Melt Options:

We have a full-pressure-sensitive adhesive that provides superior performance for high-speed labeling on labeling equipment. With good heat resistance, clean machining and high-residual tack, it offers excellent adhesion to poly bottles and labels. This product sprays extremely well and is optimal for PatternJet® or similar application systems.

The second hot melt that we offer is a full-pressure sensitive labeling adhesive that is a robust adhesive with excellent adhesion to glass and PET bottles. This adhesive is ideal for basic labeling applications such as bottled water but is not recommended for carbonated beverages.

Paper Labels:

We offer 3 different paper labeling options that are all water-based.

Water-Based Options:

The first adhesive offers fast set and excellent adhesion to PET bottles. Due to its low viscosity, semi-psa is ideal for rotary applications at medium to high speeds.

The second has excellent tack and clean machining, provides high adhesion to PET and heavily-coated glass, treated PE and PP. Its excellent cold crack resistance and very fast set speed reduces or eliminates label flagging and swimming. It delivers superior clean-ability compared to most other premium adhesives on the market.

The third Due to its low viscosity, provides consistently clean machining and machine stability with a medium open time. This product is ideal for HDPE and PP rotary labeling applications at low to moderate speeds.

Conclude:

As you can see a lot of our adhesives can be used for many different applications. Our adhesives do overlap for some applications as well. If you are in need of high quality labeling adhesives don’t hesitate to contact one of our industry experts today. We are happy to help support your business and make sure you’re using the proper adhesives on your line, so it runs as efficiently as possible.

Stay up to date with us on LinkedIn

What Adhesives Should I be Using For Assembly Applications?

Leave a CommentWhat Adhesives Should I be Using For Assembly Applications?

Before we jump into this. You may be thinking. What adhesives should I be using for assembly? It’s is a common question we hear that’s a little complex to answer without knowing more about your application. However, below are some different options that work best for assembly. We highly recommend you fill out a Contact Form before you make your decision. Our team has well over 100+ years of experience with both adhesives and equipment, and are happy to schedule a call to discuss options that would best suit your application.

Some options include:

• Mechanical (bolts, screws, tabs, rivets, crimps, pegs, nails) (These often look ugly, can rust, squeak, and even be more expensive)

• Heat (weld, braze, solder)

• Joint Design (dove tail, mortise, tenon)

• Adhere (adhesive, tape)

Why Choose An Adhesive over nuts and bolts?

• Permits joining of materials with dissimilar coefficients of expansion and contraction

• Allows components to be designed with an “invisible” means of attachment

Key Performance Factors

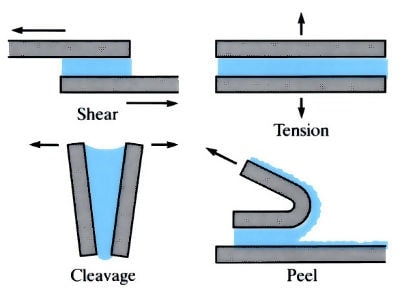

• Adhesion: Measure of bond strength between an adhesive and a substrate.

• Tack: The initial attraction or grab of an adhesive to a substrate.

• Shear: The internal or cohesive strength of an adhesive film.

Pressure-Sensitive Adhesives Advantages:

• Minimal capital costs to apply on substrates

• Provides 100% coverage for optimal adhesion to bonding area

• Can improve aesthetics by eliminating visible mechanical fasteners

• Provides structural strength that can replace bolts, rivets, welds and other mechanical fasteners

• Permits use of lighter, thinner materials

• Bond dissimilar materials without incompatibility concerns

• Acts as moisture seal/environmental barrier

• Provides uniform thickness, gap-filling properties

• Shortens assembly time and boosts productivity (eliminates the need for bonding “both” substrates together at the same time and location providing optimum manufacturing flexibility)

• Eliminates need for surface refinishing to remove weld distortions, etc.

• Provides properties and functionalities beyond joining: sound/vibration damping, thermal conductivity, anti-friction/abrasion resistance, flame retardancy

Still unsure of where to begin with your assembly adhesive needs?

Check out BC Adhesives today to learn more about what adhesives you should be using for your assembly applications. BC Adhesives offers a wide range of adhesive solutions, and has a team of industry experts with a combined 100+ years of experience who are more than willing to visit your facility and take a look at what issues you may be having.

Stay up to date with us on LinkedIn

What Are Sustainable and Eco Friendly Adhesives?

Leave a CommentSustainable/Eco Friendly Adhesive Terminology

Sustainable and Eco Friendly Adhesives are of concern to governments, business and the public all over the world. With each month that goes by, we are introduced to new, innovative ways of being ‘greener’.

On a personal level, that could be through using a reusable water bottle, shopping with bags for life or opting to buy naked products (products without packaging). On the business end, companies are switching from plastic to paper packaging, introducing vegan variations of their products and partnering with other businesses to form closed recycling loops. Companies are recognizing the change in consumer needs and behavior as well as their own accountability when it comes to the environment.

Packaging today

Packaging is one area that has a significant impact on the environment. And with packaging being a key use for adhesives, it is certainly an area worthy of further consideration and one the adhesives industry must keep on top of.

According to the US Environmental Protection Agency (EPA), food and food packaging materials make up almost half of municipal solid waste. When it comes to the damage human activity is causing the planet, packaging waste is a big part of the problem. Thankfully, documentaries such as David Attenborough’s Blue Planet are helping to highlight this and encourage people to increase their knowledge on the benefits of reusing and recycling packaging.

Most recently, however, new terms such as ‘biodegradable’, ‘compostable’ and ‘bio-based’ have surfaced for both packaging materials and adhesives alike, yet the knowledge behind these terms is rather hazy. It has become clear that consumers need more information about materials and more instructions to help with recycling. Today, people are opting to buy biodegradable packaged products over other forms of packaging because they have heard it’s better for the planet though, because they are incorrectly disposing of them, they are potentially doing more harm than good. Let us elaborate…

Repulpable, Renewable, Recyclable, Biodegradable, and Compostable Are Sustainable and Eco Friendly Adhesives – what do they actually mean?

Repulpable Adhesives

When an adhesive is repulpable, it means it dissolves completely in water during the paper re-pulping process. Repulpable adhesives are ideal for cardboard boxes, envelopes and other paper product applications because they are fully soluble in water. This makes these adhesives dissolve and eliminates the film or residue that is normally left behind.

Renewable Adhesives

Are derived from renewable materials, such as plants and beeswax, and have no petroleum derivatives in their formulations. In addition to a decreased carbon footprint, they further enhance overall sustainability content for many applications, including: Paper lamination, Case and carton sealing, and Bottle labeling.

Recyclable Adhesives

Recyclable adhesives are often used for automotive applications as well as for glass, aluminum and steel bonding needs. Recyclable adhesives are fully compatible with the substrates they are bonded to, and can be fully melted down without yielding any adhesive waste or residue when the end use product has reached its end of life.

Biodegradable Adhesives

Biodegradable adhesives are designed to be broken down by bacteria and other living organisms. During this degradation process, they lead to the production of carbon dioxide, water and other natural gases depending on the environmental conditions. Synthesized using natural raw materials and based on renewable materials, they are ideal for packaging applications, envelopes, hygiene products and medical devices especially.

Compostable Adhesives

Compostable adhesives are a subset of biodegradable adhesives. Unlike biodegradable adhesives, compostable adhesives are broken down in a compost pile environment. Designed to work in our existing waste remediation systems, these adhesives leave no harmful residue or waste behind once fully composted. The resulting compost will then be used to improve and fertilize the soil.

As environmentally friendly initiatives rise, more companies turn toward sustainable adhesives for their bonding needs. We work with many manufacturers that supply us with each of these types of sustainable adhesives that not only improve your environmental friendliness, they also increase operational efficiencies and enhance end-use products. For more information on how BC Adhesives sustainable adhesives can help your company, please visit www.bcadhesives.com

Sustainable and Eco Friendly Plastic packaging and the environment

Although plastic packaging is often torn apart by the press, it can be sustainable if used and managed in the right way. The process of converting used materials into something new keeps products away from landfill for longer, and it is often forgotten about that plastic production uses about half as much energy as alternative materials. Plastic is also a lightweight packaging medium which means less energy is needed to transport plastic packaged goods. Studies have in fact shown that the overall packaging consumption of packaging mass, energy and greenhouse gas emissions would increase if there were no plastic packaging available and only other materials were used.

The drawback to ‘standard’ plastics (and also paper) is that they can only be recycled a few times before they are deemed unusable whereas materials such as glass, metal and aluminum can be recycled endlessly.

Whilst single-use plastics are now widely known to be hazardous to the environment – especially our oceans – plastic packaging is evolving. You can now find compostable and biodegradable plastics (though these aren’t ‘readily’ recyclable) and plastic packaging that’s 100% recyclable.

Most recently, restaurant McDonalds switched its 100% recyclable plastic straws to paper alternatives, however it’s just come to light that these paper straws aren’t yet recyclable and have to be thrown away. This is just one example of the ever-growing list of companies making ‘green changes’ but, as you can see, changes can be tricky (especially for large companies) and lots of in-depth research is needed to make informed choices.

It’s clearly a challenging time for packaging specialists and brand owners as they must get the right balance between the safety, convenience, sustainable and eco friendly adhesives of their products.

Stay up to date with us on LinkedIn

Benefits Of Using Pur Adhesives For Bookbinding

Leave a CommentBenefits Of PUR Adhesives

There are many benefits to using PUR Adhesives which we will indicate below. We will give you a deep dive of the benefits, what PUR adhesives are, why you should use them, the adhesion, the advantages of PUR ambient range and flexibility, the advantages of PUR adhesive extrusion systems, and the disadvantages of extrusion/nozzle systems. For more information or if you’re still confused please feel free to Contact Us today!

- PUR adhesives have excellent page pulls and flex values

- It bonds to coated and cross-grained stock

- Exceptional aging stability

- Impervious to print ink oil migration

- High cold and heat resistance

- Excellent lay-flat performance

- No limitation to book thickness

- Very thin application required 10-12mls vs. 25-30 mil per EVA

We’ll Explain What A PUR Adhesive Is?

- Polyurethane reactive is what it stands for

- PUR adhesives must be heated to become free flowing, like a conventional hotmelt

- The initial bond is formed as it cools and solidifies, like a conventional hotmelt

- Unlike conventional hotmelts, PUR has reactive components (Isocynate groups) which cure in the presence of humidity to form a strong elastomeric film.

- To learn more about PUR and what applications it’s best used for, click PUR APPLICATIONS

You May Ask, Why Our PUR?

- Our PUR works well with recycled papers which have shorter fibers which are difficult to bond

- The amount of paper fibers are being reduced

- Multiple coatings to build paper thickness and improve print graphics

- Residual print oils can attack traditional binding adhesives

- Peace of mind for the trade binder

A Few Adhesion Outcomes:

- First of all, it will bond to glossy, coated papers and some films

- Extremely high page pull values – paper failure

- Extremely high flex test values 1,000+ flexes

A Few Advantages of PUR Ambient Range and Flexibility Include:

- PUR adhesives have a typical heat resistance of 350F peel failure versus 165-200F for quality EVA

- Typical cold crack measured at -20F versus 30F for quality EVA

- Excellent flexibility/layflat characteristics

- Comparable to true Otabind if applied properly

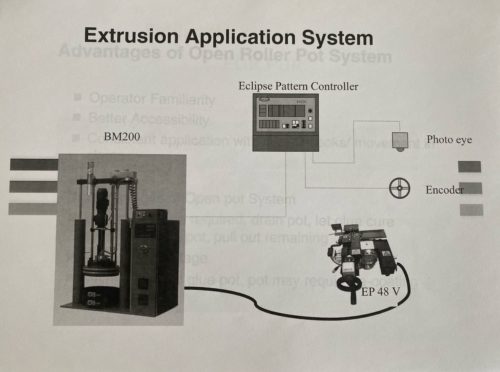

A Few Advantages of PUR Extrusion System Include:

- Easier clean up, wipe grease on slot, close slot at end of shift

- Less glue spoilage

- Precise glue cutoff, less glue buildup on three-knife blades

A Few Disadvantages Of Extrusion/Nozzle Systems Include:

- Slightly more complicated

- Requires some maintenance, valve replacement

- Less visibility

Stay up to date with us on LinkedIn