August 2021 Supply Chain Update

BC Adhesives Supply Chain Update August 2021

If you are completely new to adhesives/manufacturing, you should ask your operator if he/she has checked your applications adhesive fiber-tear. It may seem silly to tear open cases, cartons, etc… but it can save you endless amounts of costs in the long-run if your fiber-tear isn’t good. What is fiber-tear you may ask? Fiber-tear is simply what the substrate looks like when broken/torn open.

The main things to look for and report when auditing are dried beads of adhesive, the length of the bead, the width of the bead, and the weight of the adhesive that you are applying. The best type of fiber-tear is seeing little to no adhesives. If you see clumped up beads of adhesive, thicker width and longer beads, it means that you need to make adjustments on your adhesive dispensing system because you are probably over using. In most cases this would be a Nordson Pro Blue melter.

The answer to this is simple. People generally don’t check fiber-tear because their cases, cartons, etc… aren’t popping open. However, even if you aren’t experiencing any pop opens you should still be checking fiber-tear and doing monthly/quarterly audits to see if their are ways to cut costs on your operations. Generally, when operators are experiencing pop opens they tend to increase their adhesive output, but this is actually the wrong thing to do. When experiencing pop opens, check your fiber-tear and show it to your plant manager. If you are seeing abnormally thicker and longer beads, and dried clumps of adhesive. They can then reach out to the BC Adhesives team so they can come in and do an audit to help solve the issue that’s occurring.

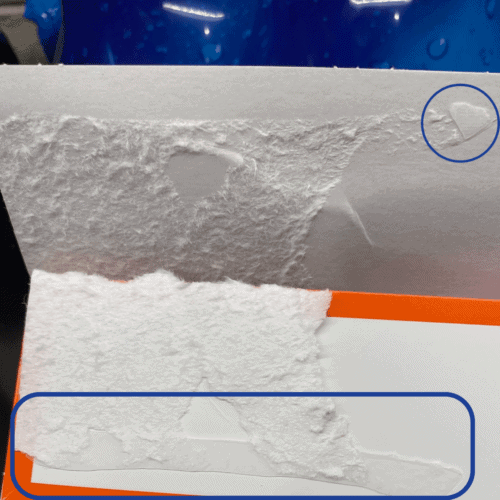

As you can see in blue circles listed in the image below, the fiber tear is not good at all, and the adhesive bead is very dried up and visible. Generally you don’t want to see a bead this long, or see any of the adhesive. BC Adhesives helped the situation by improving the fiber-tear to show none of the adhesive bead, and more of the substrate breaking rather than the adhesive breaking.

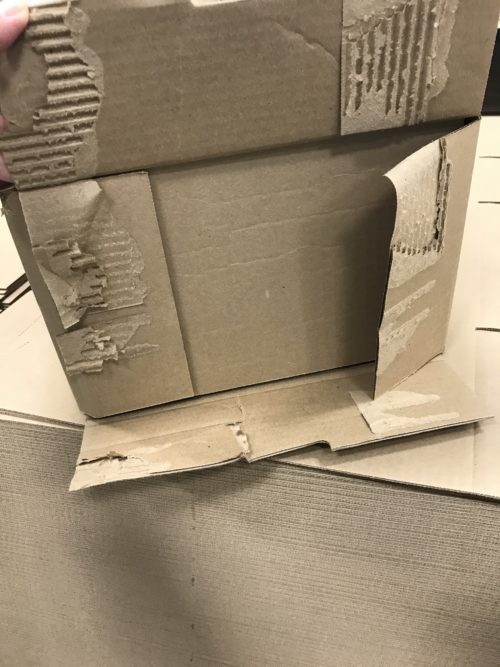

Above explains what bad fiber tear looks like, and below explains what good fiber-tear looks like. If you look at the image below you can see that the adhesive bond didn’t break, but the substrate broke. You don’t see any dried clumps/beads of adhesive which is great. By having good fiber-tear you are running efficient, not experiencing pop opens, and ultimately saving costs. If your companies fiber-tear looks more like the image above, give BC Adhesives a call today, or fill out this form.

There are many factors that may influence your decision as to what adhesive supplier you should work with. This article will go over some key factors that are important to think about when making your decision. Some important qualities to look for include: Lead time, location, service, expertise, and then price.

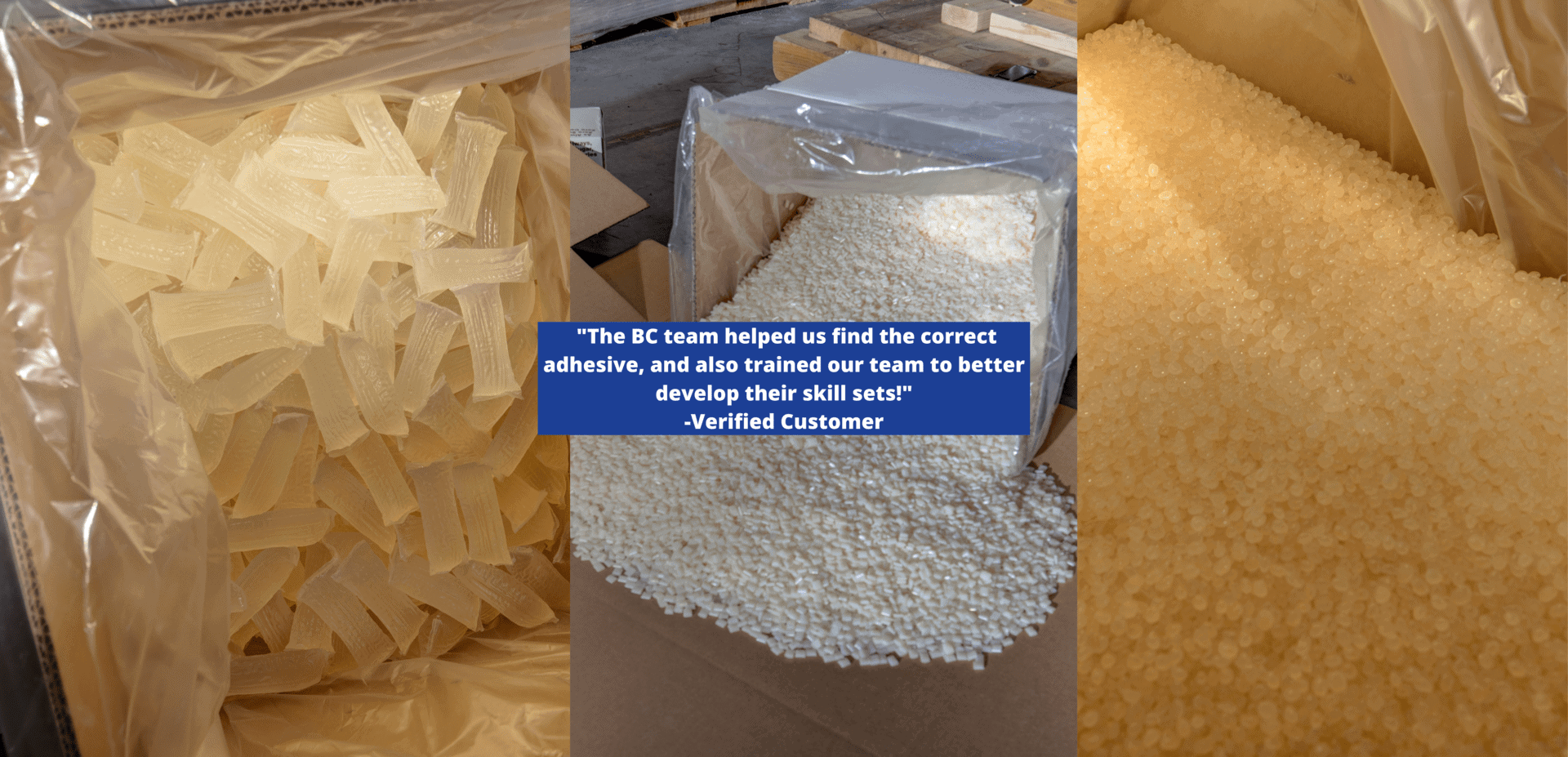

Lead time is a critical factor when choosing an adhesive supplier to work with. If you’re constantly on hold and running out of product with your current supplier, then it may be time to go “shopping” for a new one. BC Adhesives has many testimonials that showcase why they are so great to work with. Lead time is one of those factors. The team is very transparent and honest with you from the beginning and make sure that your facility never runs out of product. As a supplier we know how important lead time is to you which is why we have our warehouse fully stocked with product at all times to support the demands of customers. If you take a look at BC Adhesives Success Stories, you will see that the team goes above and beyond for each of its customers no matter how big or small. The team will deliver product on Christmas day if need be, that’s how customer focused the team at BC is.

Location is another important factor to consider when choosing the right supplier. Shipping is one of the biggest factors that may influence your purchasing decision with one supplier over another. Make sure that you discuss logistics and shipping rates before locking into a contract with your supplier. Lucky for you, BC Adhesives has partners across the country, and you may qualify for cheaper rates if BC can dropship the products to you. To learn more about location, shipping rates, and possible dropship opportunities we recommend reaching out to BC Adhesives.

Service is another important aspect that may be overlooked when choosing a supplier. A lot of suppliers compete on price up front, and don’t know how to service you. Service and reducing your operating costs are more attractive in the longterm. BC Adhesives prides itself on being an added partner to your organization. Not only figuring out what adhesive is best for your application, but actually servicing you at any given time. Whether that’s training your team on how to best use your equipment, or coming in quarterly to take a look at your equipment and seeing if you’re running as efficiently as possible. Unlike others, our goal at BC Adhesives is to make sure your equipment is running as efficiently as possible, which in turn allows you to spend less money on adhesives from us. We don’t want you to have any waste. The team strives itself on being a full service partner to your team. The sales representative that’s assigned to you will be available by phone at any time to service your needs.

Adhesive expertise is critical when working with a supplier. It’s important to ask for testimonials, look at Success Stories, and even ask for references to call on before making your decision. What separates BC Adhesives from other suppliers is that they are a diverse team combining 100+ years of experience. That’s not only adhesive experience, but equipment experience as well. The team prides itself on being a service provider to your organization. The team can definitely find you the proper adhesive for your application, but coming in and servicing your equipment at no added cost is something to look for. Sometimes it may be hard to find a full service supplier that cares about minimizing your spend on adhesives, but that’s BC Adhesives main priority. Working on your equipment and making sure you’re not overusing or underusing your adhesive.

There is price upfront, and price in the long-run. Customers who are the best fit for BC Adhesives are those who are most concerned about the longterm price savings. Short term cheaper pricing on adhesives without services will ultimately make you pay more in the long-run. The BC team focuses on saving you money on your operating costs than the adhesives itself. Why you may ask? Well, it’s because decreased operating costs are more substantial than a few cent reduction here or there on an adhesive. It’s important to factor in all of the points mentioned above to ensure that you find a trustworthy partner that will do anything to help your organization.

To find out more about BC Adhesives, and learn how the team can help you find the proper adhesive solution for your application visit: https://www.bcadhesives.com/

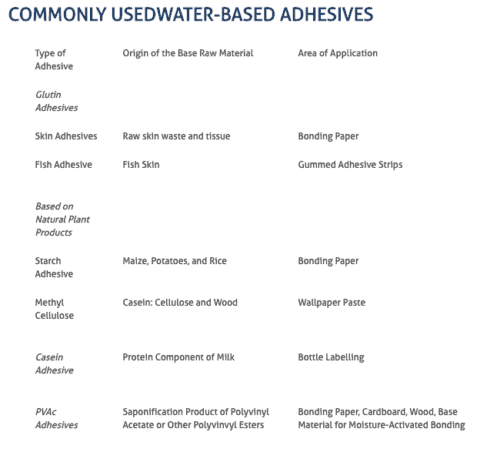

There are many scenarios where you should be using be using water-based adhesive. However, with everything there are pros and cons. The first thing to note is that Water-based adhesives can either be natural polymers meaning they are from plant-based sources such as (dextrins, starches), protein based sources (casein, blood, fish, soybean, milk albumen), or even animal based sources (hides, or bones). Water-based adhesives can also be from soluble polymers which include polyvinyl alcohol, cellulose ethers, methylcellulose, carboxymethylcellulose, and polyvinylpyrrolidone.

As previously stated, water-based adhesives can be used for a wide range of industries. Back in the day water-based adhesives were the only option to choose from until hot melt adhesives came along. Hot melts are more common now, but water-based still work for a variety of applications and industries. For example, in the bookbinding and graphic arts industries, water-based adhesives are great for keeping the consistency. The manufacturers we work with are providing us solutions that are very durable, temperature and moisture resistant and have a strong adhesion to an abundance of different substrates.

BC Adhesives has a comprehensive product portfolio formulated to exceed industry standards on specific paper stocks, films and bookcase materials. Beginning with the adhesive and continuing through the technical support and new product development. BC Adhesives we offers:

Overall, as a company we focus on bottom-line savings, while optimizing adhesive performance.

How books are made and consumed by people have changed over the years. It started with large runs on a single item and have now moved to small-scale production of many different printed material. The products we provide our customers our crafted to provide clean running products that have no stringing and good lay flat. Our products form a durable adhesive bond on both standard and digitally-printed paper. They also overcome potential adhesion issues resulting from the use of fusing oils and coatings. Our technical specialists work within the graphic arts industry researching and developing new products to achieve optimum performance.

As stated in a previous blog post, consumers are looking for better and more eye catching food packaging. New brands pop up all of the time, and consumers are always looking for new options. As consumers search the shelves for products often times the packaging implements whether they buy the product or not. Overall, consumers want functionality and convenience factors when it comes to packaging. Some key traits that customers and companies are looking for are sustainable solutions and food safety packaging. BC Adhesives Understands how these regulations extend to adhesives, sealants and functional coatings. Our manufacturers are choosing solutions to protect quality and assure safety to achieve high performance and maximize value of their products.

Navigating these packaging needs, manufacturers are partnering with suppliers who deliver solutions to support their consumer-centric agenda. BC Adhesives, sealants and functional coatings play a key role in beverage and container labeling, end-of-line packaging and metal packaging.

Screws and nails are methods of the past, and water-based adhesives can help produce lighter products, structures, and even improve quality, efficiency and sustainability for your furniture and building components. BC Adhesives supports a variety of wooden parts in many applications in the furniture industry. The team is a top solutions provider to the assembly industry and keeps its customers in mind when making decisions ensuring a true partnership.

Many industries and applications can benefit from water-based adhesives. Packaging, bookbinding, labeling, and woodworking are common places where water-based adhesives could be used. However, when deciding whether to use a water-based adhesive over a hot-melt we suggest reaching out to and industry leader in the adhesive space, BC Adhesives. The team has been in the industry since inception, and will become a great partner to your organization. The team will walk you through the benefits and drawbacks to water-based adhesives and help you make the decision based off your application. When working with assembly applications water-based adhesives serve an important role especially in woodworking and furniture products. They also work well with the graphic arts industry. Some pros to water-based adhesives are its ability to set quickly and form strong bonds that, unless exposed directly to excess water or moisture, will remain strong for an extended period of time. To find out if water-based adhesives are right for your application reach out to BC Adhesives.

There are 10 precious tips that you need to consider when looking for an adhesive/adhesive supplier. It all starts with application. Often times, most people turn to Google to see what would work best for their application, but this is a bit tricky and not always the most accurate way to do it. We recommend contacting an adhesive distributor with years of experience who can run tests to see what adhesive will work best for your application.

There are many adhesive distributors out there who work with a lot of the same manufacturers. Often times, it’s best to choose a distributor who also is a great partner to your organization. This would be someone who has years of expertise working with equipment and adhesives. The worst case scenario is buying cheap adhesive from a distributor that doesn’t have much of an idea of how your equipment runs. Everyone can offer you the same adhesive and compete on price, but that may not always be the best option for your company, especially if you are newer and not as established quite yet. As stated earlier, the best adhesive distributors are those who don’t compete on price. They are the ones who will be saving you money in the long run by reducing your downtime and making sure your adhesive is running efficiently at all times.

Success stories, and testimonials are important factors to look at when deciding what supplier to work with. BC Adhesives, has a wide range of testimonials, and success stories that prove why they are the best adhesive supplier across the globe. It’s important to think of your adhesive distributor as an employee, someone who you would trust to be apart of your team. The BC team has been nothing short from perfect in providing quality adhesives and top notch service. Below is an example, of one of their recent success stories: ” A Plant contacted BC Adhesives Friday night at 7PM. Their pump was sticking on the glue system which made the plant operation go down, costing thousands of dollars. Our sales representative advised on how to lubricate the pump to revive it to get back running. In result, the plant was up and running within minutes. The team also advised on replacements parts to prevent future downtime.” This is what a partnership is. A team that’s willing to help you on their own dime to make sure you are taken care of. If you didn’t notice, this call had nothing to do with the actual adhesive itself, but the equipment.

It’s important to be prepped before talking with a potential adhesive specialist. The first question you should be prepped for is What substrates are you bonding? Following that, they will ask a few others that will give them a better idea as to what adhesive would be best for your application. Some may be easier to answer than others, but as long as you have a general idea on what you’re using the adhesive for, industry experts should be able to provide you a benefit.

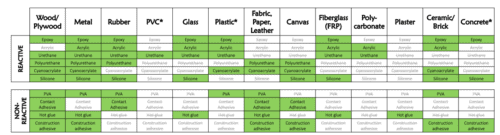

There are guides for adhesives, all over the internet, but the one below showcases a variety of different applications. Use this chart as a guide to get the conversation going with an adhesive specialist. If you don’t know much about adhesive, this guide is perfect for you!

We’ve gone through a lot so far, and this is just one drop in the bucket, but it’s important to look at what services an adhesive partner can offer other than just providing you adhesives. It’s more money in your pocket in the long-run if you pay a little extra up front for your product, but have the benefits of a full service team to help you when your in a jam. BC Adhesives, is that full service partner that you are looking for. A team that will be there for you 24/7 to make sure you are running as efficiently as possible. You won’t have to worry about anything when working with BC Adhesives, rest assured as they will be the ones helping you in good times and bad.

Curious to learn how food packaging influences buyer behavior? Check out the “Five Things Nobody Told You About How Food Packaging Affects Consumers”

Did you know that food packaging has an effect on people’s intent to purchase it or not. It may sound funny, but it’s true and nowadays it’s getting more and more difficult to stand out on a crowded shelf with new snacks and brands forming each day. Today, newer brands need to invest heavily into their packaging design because it’s the most important form of marketing. Not only that, but it’s the first view point consumers see when browsing the shelves at the grocery store. Brands that have terrible packaging often times fail because consumers don’t tend to look at them. It’s the packaging that captures someones attention when walking down the aisle. When deciding what type of packaging you should use or what budget to spend on packaging you should first mock up a design or color scheme that you want to portray to your customers. Color schemes are very important when it comes to catching someones attention. Usually the brighter more vibrant colors tend to work better than generic colors, but it’s important to look at competitors in your space before making the final decision. You must ask yourself a few questions before deciding what design to choose. It’s also important to do a competitive analysis of all the brands that compete for shelf life in your space. Look at their packaging and pick out things you like, don’t like, etc… From there you will have a better idea on how to make yours stand out. Who knew all of these details had to be done before deciding what food packaging design you should create.

Material is the second most important factor that nobody would think affects their customers decision making, but it’s critical. It’s different for all categories, but some of the most common food packaging material includes trays, bags, boxes, cans, cartons, etc… In most cases trays and cartons are mean’t for plant seeds, meats, and beverages. Bags, boxes, and cans are more common for foods that go on the shelves such as chips, crackers and nuts. Other material that’s important to think about is the actual adhesive that holds each of these together. Adhesives are essential for a variety of food packaging needs. Adhesives aren’t often thought about often, but can have a huge affect on your customer. Generally speaking, you want an adhesive that doesn’t build residue on the outside of the packaging, but also doesn’t give out on you leading to opened boxes. Our recommendation is to consult with an adhesive expert to learn what adhesive would be best for your application. BC Adhesives is an industry leader in the adhesive space for food packaging. The team is very hands on in the process as they will do the dirty work in finding/testing adhesive that will be both attractive, lower cost, and higher efficiency over any other adhesive supplier out there. The team has 100+ years of adhesive and equipment experience, and will come out to your plant anytime to work on the equipment to make sure it runs as efficiently as possible.

Food packaging has a crucial impact to the environment, and customers care about it. When deciding to buy from your brand or your competitors brand its important to win them over with green packaging. 70% of people are more likely to switch to a brand that’s focusing on bettering earth. Brands must think of younger demographics in their packaging choice. Studies have shown that packaging is buried in a landfill or becomes litter that is carried out through our environment. You should use recycled or reusable material for your packaging. This not only betters the planet, but also makes your marketing stand out. Besides the physical structure of your packaging, you need to also look at what holds your package together. One of the main ways packages are held is with adhesive. Fortunately there are many sustainable adhesives to work with. BC Adhesives not only educates you about adhesive, but will help you choose the correct one for your product needs.

The size of your packaging is very important. We like to say, the smaller the better. As stated earlier, shelf space is hard to come by, and shipping charges are increasing all of the time. A small, and light design will give you shelf space, and will also reduce shipping costs, and adhesive costs. The FDA lists the different size options for each category. You need to make sure that if you have a small package, that your text/copy is still large enough to see. When people have to squint to read your packaging it’s telling you two things. One, you may be hiding something, or two your packaging design is too crowded. Make sure to try and limit the amount of text that goes on your packaging and make sure the spacing between different sections is enough.

Simple is always better! Don’t over complicate things. One, it could make your packaging look too crowded, and two it can give the consumer a bad read on what you’re offering. Accessibility is also an important trait. Easy open and close technology, no residue from adhesive, and no need for a scissors or knife to open. You may not think this, but it’s important. Implementing technology into your packaging is continuing to increase as it makes it easier for users to open and close. Arrows, tabs, or seals are now necessary to have as they require minimal effort to open. Again, this all comes down to the design of your package. The shape, size, and adhesive have a great impact on making your packaging more accessible to consumers. You don’t want too strong of adhesive, and you also don’t want to underuse adhesive because it will cause your packaging to open too quickly. Contact BC Adhesives today if you’re looking to step up your packaging game for your customers. This will save you money, increase equipment efficiency, and make you run instead of being down for maintenance. Step up your packaging, your consumers care. Increase your margins with BC today!

The history of hot melt adhesive goes back to 1940 when Procter & Gamble, Paul Cope invented the thermoplastic glue as an improvement of water-based adhesives that were failing humid climates. This changed the direction the industry was going. You can now use 100% solid, non-toxic adhesives containing no solvents or water, to provide permanent bonding to a wide range of materials. In the past glue was used for a few applications, but now with the introduction of hot melt adhesive, it now is used in almost every industry in some way, shape, or form. If you think about it, adhesives are essential for most businesses to even function, as there isn’t really an alternative to them. A simple way to learn the functionality of how hot melt adhesives work, check out this video “How Do Hot Melt Adhesives Work”

The packaging industry has always dominated the hot melt adhesive usage. Back in the day there were many ways hot melt adhesives were applied. This made it confusing for users to figure out what equipment they should be using. It started with hot melt hand guns. These were used for basic packaging applications. Then it shifted to high power melt sticks, self contained hot melt guns, hot melt tanks, etc… You may be wondering what hot melt system should I be using for my application? This is a common question, and to be honest, it’s different for every industry. However, most hot melts for the packaging industry use Nordson equipment. Whereas, assembly applications could use an automated spray application or extrusion system.

We were all using water-based adhesives until hot melts we’re created. Hot melt adhesives were created because it offers many advantages to an abundance of applications that make them better than water-based adhesives. Some advantages include: longer shelf life, no loss of thickness during solidification, lower shipping costs, and it eliminates the drying or curing step. You may be saying to yourself why would people use water-based adhesives anymore? Well, other types of adhesives may be a better choice if you use on substrates that are sensitive to higher temperatures, as well as end-products that can be exposed to higher temperatures, chemicals, or weather conditions where an HMA may offer less bond strength or resistance.

As always, when you work with something for a long time there will be a time where issues arise. This happens with everything, and there isn’t really a way to avoid it, unless you are taking care of your equipment and making sure it’s running as efficiently as possible. Most users may not be total experts on adhesive equipment, but have the general gist of how to run the machine. The team over at BC Adhesives are experts at both suggesting you the correct adhesive, and optimizing your equipment so it runs as efficiently as possible. As a general rule of thumb, cold temperatures can definitely affect the performance of pressure sensitive adhesives. We recommend adding a glue pressure gauge to monitor your dispenser’s performance to detect signs of trouble. The BC Adhesives team is happy to train your staff on our dime to show you the best ways to maintain your equipment, so you can improve efficiency, output, and reduce the downtime you have.

There are five main types of hot melt adhesives. These include EVA’s, Polyethylene, Metallocene, APAO, and Polyamides. Each of these adhesives can be used for a variety of different applications. If you are dealing with uncoated paper applications EVA’s would be a better option for you. EVA’s would be better because they offer heat and cold resistance to make it set quicker. If you’re working with carton and case sealing applications then polyethylene would be your best option because it offers excellent thermal stability and are low odor. To learn more, and if you have any additional questions on what types of hot melt you should use don’t hesitate to contact the BC Adhesives team!

Sometimes it may be hard to decide what labels you should buy. When it comes to deciding what labels work best for your bottling needs you need to first look at what the bottle is made of. If you are looking for glass bottle labels you have two options to choose from. You could go with a film label or a paper label. For film labels we generally use hot melt adhesives. We work with a variety of manufacturers to provide a full line of pressure sensitive labeling adhesives for this application.

We have a robust adhesive that has a very strong adhesion to glass and PET bottles. We generally use this adhesive for basic labeling applications such as bottled water or non carbonated beverages.

We also offer a different pressure sensitive adhesive that provides superior performance for high speed labeling on labeling equipment. This would have good heat resistance, clean machining, and high-residual tack. It also offers excellent adhesion to poly bottles and labels. This product sprays well, and is optimal for PatternJet® or similar application systems.

Our last option we recommend is a colorless, full pressure sensitive labeling adhesive that is formulated to machine well on rotary labelers. This powerful adhesive remains robust in both hot and cold end-use environments, making it suitable for a variety of applications.

If you are using paper labels for your glass applications then you can choose from water-based or hot melt adhesives. It’s hard for us to say which you should be using without looking at your line. We’re happy to give you a free line audit to help you figure out what adhesives you should be using. Just contact us!

For paper labels we have several options. We have a non-casein adhesive that is specifically developed for glass bottle labeling. It offers high wet tack that performs well on cold, wet glass bottles. It has a fast set speed, and is very easy to clean up.

Another option we have provides high adhesion to PET and heavily-coated glass, treated PE and PP. It has excellent cold crack resistance and very fast set speed reduces or eliminates label flagging and swimming. It delivers superior clean-ability compared to most other premium adhesives on the market.

We also have a highly versatile non-casein adhesive that performs well on coated and non-coated labels at a wide range of operating speeds. It offers high tack, fast set speed and clean machining for more efficient operation. It also offers unparalleled ice resistance and is available in different viscosity ranges.

Other than water-based options we also have some hot melts that work well too. We supply a full-pressure sensitive labeling adhesive that is a robust adhesive with excellent adhesion to glass and PET bottles. This adhesive is ideal for basic labeling applications such as bottled water but is not recommended for carbonated beverages.

We also have another full-pressure-sensitive adhesive that provides superior performance for high-speed labeling on labeling equipment. With good heat resistance, clean machining and high-residual tack, it offers excellent adhesion to poly bottles and labels. This product sprays extremely well and is optimal for PatternJet® or similar application systems.

Our last hot melt that we recommend for paper labels is a colorless, full-pressure sensitive labeling adhesive that is formulated to machine well on rotary labelers. This powerful adhesive remains robust in both hot and cold end-use environments, making it suitable for a variety of application processes.

When working with metal containers there are two film labels that we recommend. They are two different hot melts.

We have a full-pressure-sensitive adhesive that provides superior performance for high-speed labeling on labeling equipment. With good heat resistance, clean machining and high-residual tack, it offers excellent adhesion to poly bottles and labels. This product sprays extremely well and is optimal for PatternJet® or similar application systems.

Another option we have is a full-pressure sensitive labeling adhesive is a robust adhesive with excellent adhesion to glass and PET bottles. This adhesive is ideal for basic labeling applications such as bottled water but is not recommended for carbonated beverages.

We do not recommend using any water-based adhesives for metal containers.

For Paper labels we offer three different hot melts.

We use one which is the industry standard in roll-through labeling, this hot-melt non-permanent adhesive is designed for convenient, easy use. With an aggressive tack, it offers excellent, reliable label pick up.

We also have a roll-through labeling product offers the same high performance, but is formulated with a different raw material slate for optimal supply security. This non-permanent product offers excellent hot tack and good thermal stability for open pot applications.

Our last hot melt option is a permanent adhesion pick up for roll-through labeling applications. It has high tack properties ensuring optimal performance for high-speed applications. Because it machines cleanly, this hot-melt adhesive is ideal for swirl spray label application as well.

We have four different film labels that we recommend using for PET bottles. They are all hot melts.

The first options is our highest performing semi-pressure sensitive labeling adhesive. It is ideal for carbonated beverage bottles. The combination of low-melt viscosity and high cohesive strength ensures complete wet-out on the label while eliminating flagging during the filling process.

The second option we recommend is a full-pressure sensitive labeling adhesive. It is a robust adhesive with excellent adhesion to glass and PET bottles. This adhesive is ideal for basic labeling applications such as bottled water but is not recommended for carbonated beverages.

The third option is a full-pressure-sensitive adhesive that provides superior performance for high-speed labeling on labeling equipment. With good heat resistance, clean machining and high-residual tack, it offers excellent adhesion to poly bottles and labels. This product sprays extremely well and is optimal for PatternJet® or similar application systems.

The fourth option is a colorless, full-pressure sensitive labeling adhesive is formulated to machine well on rotary labelers. This powerful adhesive remains robust in both hot and cold end-use environments, making it suitable for a variety of application processes.

For paper labels we offer 3 different hot melts and 3 different water-based adhesives that can be suitable for your application.

The first water-based option we offers fast set and excellent adhesion to PET bottles. Due to its low viscosity, semi-psa is ideal for rotary applications at medium to high speeds.

The second water-based option has excellent tack and clean machining. It provides high adhesion to PET and heavily-coated glass, treated PE and PP. Its excellent cold crack resistance and very fast set speed reduces or eliminates label flagging and swimming. It delivers superior clean-ability compared to most other premium adhesives on the market.

The third water-based option we have is an excellent choice for PET. It’s a water-based adhesive that provides consistently clean machining and machine stability with a medium open time. This product has a medium tack and is best suited for rotary applications at medium speeds.

The first hot melt that we recommend is a full-pressure sensitive labeling adhesive that is a robust adhesive with excellent adhesion to glass and PET bottles. This adhesive is ideal for basic labeling applications such as bottled water but is not recommended for carbonated beverages.

The second one that we recommend is a full-pressure-sensitive adhesive provides superior performance for high-speed labeling on labeling equipment. With good heat resistance, clean machining and high-residual tack, it offers excellent adhesion to poly bottles and labels. This product sprays extremely well and is optimal for PatternJet® or similar application systems.

The third we recommend is a colorless, full-pressure sensitive labeling adhesive is formulated to machine well on rotary labelers. This powerful adhesive remains robust in both hot and cold end-use environments, making it suitable for a variety of application processes.

We offer 2 hot melt adhesives for film labels.

We have a full-pressure-sensitive adhesive that provides superior performance for high-speed labeling on labeling equipment. With good heat resistance, clean machining and high-residual tack, it offers excellent adhesion to poly bottles and labels. This product sprays extremely well and is optimal for PatternJet® or similar application systems.

The second hot melt that we offer is a full-pressure sensitive labeling adhesive that is a robust adhesive with excellent adhesion to glass and PET bottles. This adhesive is ideal for basic labeling applications such as bottled water but is not recommended for carbonated beverages.

We offer 3 different paper labeling options that are all water-based.

The first adhesive offers fast set and excellent adhesion to PET bottles. Due to its low viscosity, semi-psa is ideal for rotary applications at medium to high speeds.

The second has excellent tack and clean machining, provides high adhesion to PET and heavily-coated glass, treated PE and PP. Its excellent cold crack resistance and very fast set speed reduces or eliminates label flagging and swimming. It delivers superior clean-ability compared to most other premium adhesives on the market.

The third Due to its low viscosity, provides consistently clean machining and machine stability with a medium open time. This product is ideal for HDPE and PP rotary labeling applications at low to moderate speeds.

As you can see a lot of our adhesives can be used for many different applications. Our adhesives do overlap for some applications as well. If you are in need of high quality labeling adhesives don’t hesitate to contact one of our industry experts today. We are happy to help support your business and make sure you’re using the proper adhesives on your line, so it runs as efficiently as possible.

Stay up to date with us on LinkedIn

Before we jump into this. You may be thinking. What adhesives should I be using for assembly? It’s is a common question we hear that’s a little complex to answer without knowing more about your application. However, below are some different options that work best for assembly. We highly recommend you fill out a Contact Form before you make your decision. Our team has well over 100+ years of experience with both adhesives and equipment, and are happy to schedule a call to discuss options that would best suit your application.

• Mechanical (bolts, screws, tabs, rivets, crimps, pegs, nails) (These often look ugly, can rust, squeak, and even be more expensive)

• Heat (weld, braze, solder)

• Joint Design (dove tail, mortise, tenon)

• Adhere (adhesive, tape)

• Permits joining of materials with dissimilar coefficients of expansion and contraction

• Allows components to be designed with an “invisible” means of attachment

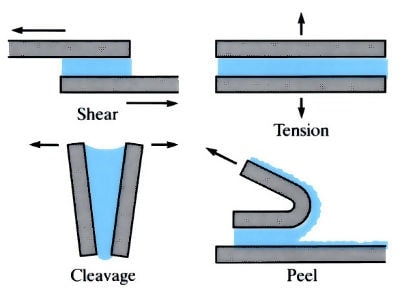

• Adhesion: Measure of bond strength between an adhesive and a substrate.

• Tack: The initial attraction or grab of an adhesive to a substrate.

• Shear: The internal or cohesive strength of an adhesive film.

• Minimal capital costs to apply on substrates

• Provides 100% coverage for optimal adhesion to bonding area

• Can improve aesthetics by eliminating visible mechanical fasteners

• Provides structural strength that can replace bolts, rivets, welds and other mechanical fasteners

• Permits use of lighter, thinner materials

• Bond dissimilar materials without incompatibility concerns

• Acts as moisture seal/environmental barrier

• Provides uniform thickness, gap-filling properties

• Shortens assembly time and boosts productivity (eliminates the need for bonding “both” substrates together at the same time and location providing optimum manufacturing flexibility)

• Eliminates need for surface refinishing to remove weld distortions, etc.

• Provides properties and functionalities beyond joining: sound/vibration damping, thermal conductivity, anti-friction/abrasion resistance, flame retardancy

Check out BC Adhesives today to learn more about what adhesives you should be using for your assembly applications. BC Adhesives offers a wide range of adhesive solutions, and has a team of industry experts with a combined 100+ years of experience who are more than willing to visit your facility and take a look at what issues you may be having.

Stay up to date with us on LinkedIn

Sustainable and Eco Friendly Adhesives are of concern to governments, business and the public all over the world. With each month that goes by, we are introduced to new, innovative ways of being ‘greener’.

On a personal level, that could be through using a reusable water bottle, shopping with bags for life or opting to buy naked products (products without packaging). On the business end, companies are switching from plastic to paper packaging, introducing vegan variations of their products and partnering with other businesses to form closed recycling loops. Companies are recognizing the change in consumer needs and behavior as well as their own accountability when it comes to the environment.

Packaging is one area that has a significant impact on the environment. And with packaging being a key use for adhesives, it is certainly an area worthy of further consideration and one the adhesives industry must keep on top of.

According to the US Environmental Protection Agency (EPA), food and food packaging materials make up almost half of municipal solid waste. When it comes to the damage human activity is causing the planet, packaging waste is a big part of the problem. Thankfully, documentaries such as David Attenborough’s Blue Planet are helping to highlight this and encourage people to increase their knowledge on the benefits of reusing and recycling packaging.

Most recently, however, new terms such as ‘biodegradable’, ‘compostable’ and ‘bio-based’ have surfaced for both packaging materials and adhesives alike, yet the knowledge behind these terms is rather hazy. It has become clear that consumers need more information about materials and more instructions to help with recycling. Today, people are opting to buy biodegradable packaged products over other forms of packaging because they have heard it’s better for the planet though, because they are incorrectly disposing of them, they are potentially doing more harm than good. Let us elaborate…

When an adhesive is repulpable, it means it dissolves completely in water during the paper re-pulping process. Repulpable adhesives are ideal for cardboard boxes, envelopes and other paper product applications because they are fully soluble in water. This makes these adhesives dissolve and eliminates the film or residue that is normally left behind.

Are derived from renewable materials, such as plants and beeswax, and have no petroleum derivatives in their formulations. In addition to a decreased carbon footprint, they further enhance overall sustainability content for many applications, including: Paper lamination, Case and carton sealing, and Bottle labeling.

Recyclable adhesives are often used for automotive applications as well as for glass, aluminum and steel bonding needs. Recyclable adhesives are fully compatible with the substrates they are bonded to, and can be fully melted down without yielding any adhesive waste or residue when the end use product has reached its end of life.

Biodegradable adhesives are designed to be broken down by bacteria and other living organisms. During this degradation process, they lead to the production of carbon dioxide, water and other natural gases depending on the environmental conditions. Synthesized using natural raw materials and based on renewable materials, they are ideal for packaging applications, envelopes, hygiene products and medical devices especially.

Compostable adhesives are a subset of biodegradable adhesives. Unlike biodegradable adhesives, compostable adhesives are broken down in a compost pile environment. Designed to work in our existing waste remediation systems, these adhesives leave no harmful residue or waste behind once fully composted. The resulting compost will then be used to improve and fertilize the soil.

As environmentally friendly initiatives rise, more companies turn toward sustainable adhesives for their bonding needs. We work with many manufacturers that supply us with each of these types of sustainable adhesives that not only improve your environmental friendliness, they also increase operational efficiencies and enhance end-use products. For more information on how BC Adhesives sustainable adhesives can help your company, please visit www.bcadhesives.com

Although plastic packaging is often torn apart by the press, it can be sustainable if used and managed in the right way. The process of converting used materials into something new keeps products away from landfill for longer, and it is often forgotten about that plastic production uses about half as much energy as alternative materials. Plastic is also a lightweight packaging medium which means less energy is needed to transport plastic packaged goods. Studies have in fact shown that the overall packaging consumption of packaging mass, energy and greenhouse gas emissions would increase if there were no plastic packaging available and only other materials were used.

The drawback to ‘standard’ plastics (and also paper) is that they can only be recycled a few times before they are deemed unusable whereas materials such as glass, metal and aluminum can be recycled endlessly.

Whilst single-use plastics are now widely known to be hazardous to the environment – especially our oceans – plastic packaging is evolving. You can now find compostable and biodegradable plastics (though these aren’t ‘readily’ recyclable) and plastic packaging that’s 100% recyclable.

Most recently, restaurant McDonalds switched its 100% recyclable plastic straws to paper alternatives, however it’s just come to light that these paper straws aren’t yet recyclable and have to be thrown away. This is just one example of the ever-growing list of companies making ‘green changes’ but, as you can see, changes can be tricky (especially for large companies) and lots of in-depth research is needed to make informed choices.

It’s clearly a challenging time for packaging specialists and brand owners as they must get the right balance between the safety, convenience, sustainable and eco friendly adhesives of their products.

Stay up to date with us on LinkedIn