Cutting adhesive costs by checking fiber-tear

Why should I check fiber-tear?

If you are completely new to adhesives/manufacturing, you should ask your operator if he/she has checked your applications adhesive fiber-tear. It may seem silly to tear open cases, cartons, etc… but it can save you endless amounts of costs in the long-run if your fiber-tear isn’t good. What is fiber-tear you may ask? Fiber-tear is simply what the substrate looks like when broken/torn open.

What to look for when checking fiber tear?

The main things to look for and report when auditing are dried beads of adhesive, the length of the bead, the width of the bead, and the weight of the adhesive that you are applying. The best type of fiber-tear is seeing little to no adhesives. If you see clumped up beads of adhesive, thicker width and longer beads, it means that you need to make adjustments on your adhesive dispensing system because you are probably over using. In most cases this would be a Nordson Pro Blue melter.

Why don’t most people check fiber-tear?

The answer to this is simple. People generally don’t check fiber-tear because their cases, cartons, etc… aren’t popping open. However, even if you aren’t experiencing any pop opens you should still be checking fiber-tear and doing monthly/quarterly audits to see if their are ways to cut costs on your operations. Generally, when operators are experiencing pop opens they tend to increase their adhesive output, but this is actually the wrong thing to do. When experiencing pop opens, check your fiber-tear and show it to your plant manager. If you are seeing abnormally thicker and longer beads, and dried clumps of adhesive. They can then reach out to the BC Adhesives team so they can come in and do an audit to help solve the issue that’s occurring.

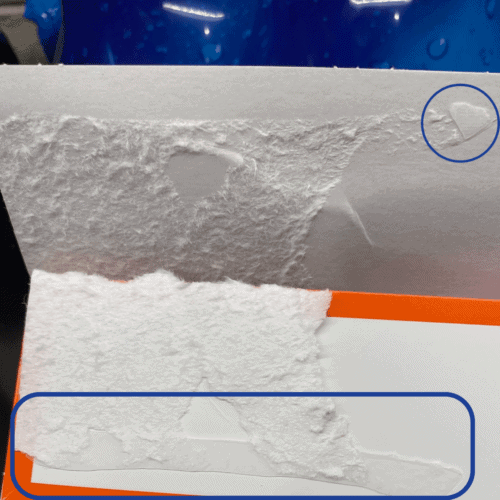

What bad fiber-tear looks like?

As you can see in blue circles listed in the image below, the fiber tear is not good at all, and the adhesive bead is very dried up and visible. Generally you don’t want to see a bead this long, or see any of the adhesive. BC Adhesives helped the situation by improving the fiber-tear to show none of the adhesive bead, and more of the substrate breaking rather than the adhesive breaking.

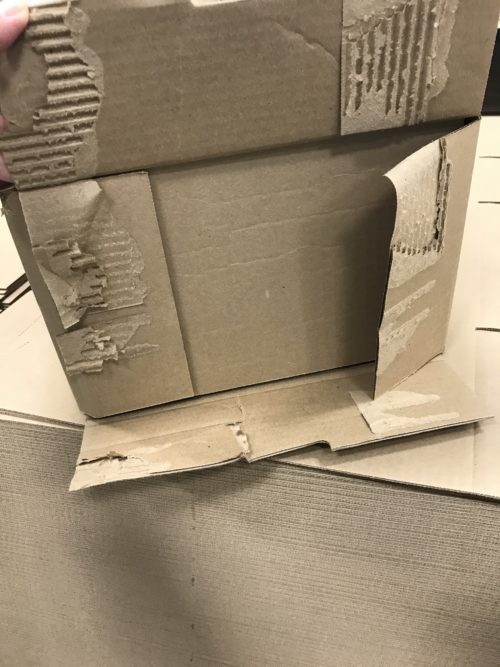

What good fiber-tear looks like?

Above explains what bad fiber tear looks like, and below explains what good fiber-tear looks like. If you look at the image below you can see that the adhesive bond didn’t break, but the substrate broke. You don’t see any dried clumps/beads of adhesive which is great. By having good fiber-tear you are running efficient, not experiencing pop opens, and ultimately saving costs. If your companies fiber-tear looks more like the image above, give BC Adhesives a call today, or fill out this form.