Product Assembly Adhesives

Product assembly

Adhesive bonding often proves a more effective, efficient, and reliable method of holding parts together than bolts or other product assembly solutions. Adhesives can connect substrates without unsightly welds or protruding nuts and bolts, which makes them more aesthetically pleasing as well.

Industries and applications

A product assembly success story

In November 2018, a potential client invited BC Adhesives to visit their worksite and observe their current adhesive application. While this particular production application had been running for 15 years, the prospective customer was interested in our evaluation of their work. We were asked to consult with their team on the current adhesive, adhesive equipment, and application process.

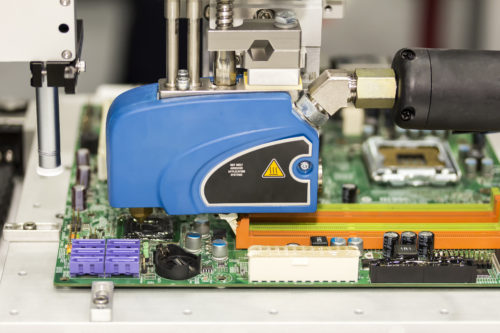

The BC team managed to make changes, improvements, and recommendations related to all areas. The primary areas of improvement included equipment setup training and equipment improvements. We worked in tandem with their team to design a new applicator bracket that allowed for improved accuracy, repeatability, and cutoff. The bracket required 10% less adhesive in order to produce better and more consistent products.

The mechanical improvements that came along with this change also reduced downstream issues. Excessive glue build-up that once led to downtime was virtually eliminated. Once we established a value proposition to our customer, we continued to look at ways to optimize their application. BC Adhesives ran a battery of tests in the lab and found a stronger adhesive that could produce a better product at a lower cost.

Our staff continues to monitor the application. This affords us the ability to help our client maintain their individualized solution. The client has multiple adhesive applications in their facility, and we have now moved into a second manufacturing process and are working through an analysis to see if we can identify more cost saving opportunities.

Our team of adhesive experts can offer insights and identify potential opportunities for improvement for your operation. For more information about product assembly services for your application, contact us today.

Building Products

Building Products Panel Assembly

Panel Assembly Woodworking Assembly

Woodworking Assembly Air or Oil Filers

Air or Oil Filers Furniture Assembly

Furniture Assembly Gasketing and Sealing

Gasketing and Sealing Aggregate Industry

Aggregate Industry Engineered Flooring

Engineered Flooring General Roll Coating or Lamination Applications

General Roll Coating or Lamination Applications Foil Lamination

Foil Lamination Garage Door Assembly

Garage Door Assembly

Vinyl Wall Base Board

Vinyl Wall Base Board