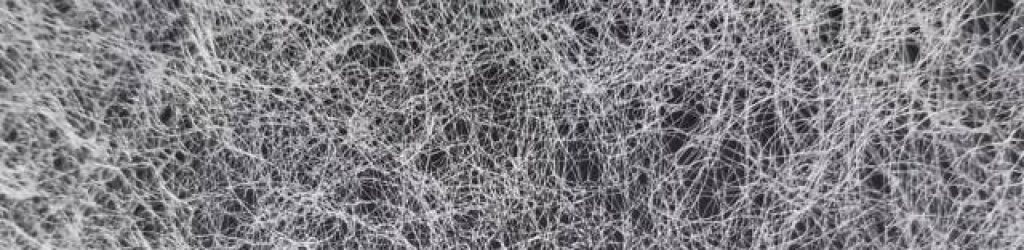

BC Adhesives create web adhesives, hot melt adhesives in a non-woven fabric-like form, using polyamide, polyester, polyolefin, and polyurethane polymers. They produce these adhesives through modified melt-blown processes for standard web adhesives or modified blown film processes. Web adhesives, with their rough surface and fine fibers, bond well to substrates, creating strong and durable bonds which are activated by heat, pressure, or a combination.

Eco-friendly adhesives provide breathability, customization, less waste, easy application, and a strong bond-to-porosity ratio. Being 100% solids, they contribute to less pollution and waste, making them a more sustainable choice. They lack harmful chemicals, need no special equipment, reduce energy use, and minimize potential hazards during application.

They work with wood, leather, foam, fabric, metals, PVC, ABS, aluminum, fiberglass, and treated PP. Choosing the right web adhesive depends on melting temperature, softening point, viscosity, resistance, weight, and fire retardancy. Activation temperatures range from 170°F to 330°F, with fire-retardant formulations available for fire-resistant applications.

BC Adhesives create web adhesives, hot melt adhesives in a non-woven fabric-like form, using polyamide, polyester, polyolefin, and polyurethane polymers. They produce these adhesives through modified melt-blown processes for standard web adhesives or modified blown film processes.

Web adhesives, with their rough surface and fine fibers, bond well to substrates and create strong, durable bonds activated by heat, pressure, or both.

Eco-friendly adhesives provide breathability, customization, less waste, easy application, and a strong bond-to-porosity ratio. Being 100% solids, they contribute to less pollution and waste, making them a more sustainable choice. They lack harmful chemicals, need no special equipment, reduce energy use, and minimize potential hazards during application.

They work with wood, leather, foam, fabric, metals, PVC, ABS, aluminum, fiberglass, and treated PP. Choosing the right web adhesive depends on melting temperature, softening point, viscosity, resistance, weight, and fire retardancy. Activation temperatures range from 170°F to 330°F, with fire-retardant formulations available for fire-resistant applications.

Several types of web adhesives serve different purposes, each offering unique properties for specific applications. Common types include:

Several types of web adhesives serve different purposes, each offering unique properties for specific applications. Common types include:

Contact us today to learn more about the Web adhesives that you should be implementing into your products! With more than two decades of experience, our trusted team can help you optimize your workflow and work towards a healthier planet.

Web adhesives are a reliable and adaptable choice for various industries and applications, as they deliver a robust and flexible bond. With their ability to withstand harsh environments and extreme temperatures, they are well-suited for projects that demand a long-lasting and durable adhesive solution.

Trust our experts to help you identify the ideal web adhesive to meet your specific requirements and achieve success in your projects.

Web adhesives offer several advantages over other adhesive types. They provide uniform adhesive distribution, ensuring strong and durable bonds across various applications. Web adhesives are versatile and adaptable, suitable for a wide range of materials and industries. They also possess gap-filling properties, temperature and environmental resistance, reduced weight, and improved aesthetics.

When choosing the right web adhesive, consider factors such as materials being bonded, application requirements, manufacturing process, and environmental conditions. Assess compatibility with specific substrates, bond strength, temperature resistance, activation temperature, processing time, and equipment needed for the application. By evaluating these factors, you can select the optimal web adhesive for your specific application, ensuring long-lasting and reliable bonds.

Web adhesives are a versatile, environmentally friendly, and efficient bonding solution for many substrates and applications. By considering factors such as melting temperatures, softening point, viscosity, solvent, and water resistance, basis weight, and fire retardancy, you can find the ideal web adhesive to meet your specific needs. To ensure the best possible results, evaluating the performance of the selected web adhesive in your application is crucial. If you need help finding the perfect web adhesive solution for your project, the experts at BC Adhesives are ready to assist you. With their extensive knowledge and experience, they can guide you through the selection process and provide tailored recommendations to ensure optimal performance and satisfaction for any application.

Please fill out the form below, and we will reply within 1 business day.