Adhesive Solutions

Find your perfect adhesive solution with BC Adhesives

With over 20 years of industry experience, our team of experts has the knowledge to help you find the ideal adhesive solution to meet your unique needs. From hot melt adhesives to eco-friendly water-based adhesives to structural adhesives, we’ve got you covered with our top-quality products. Plus, our unrivaled commitment to customer service means you can trust that BC Adhesives is the right choice for all of your adhesive needs. Say goodbye to adhesive related headaches and hello to a reliable, innovative solution with BC Adhesives!

Let Us Help You Find The Perfect Solution

Hot melt adhesives

Discover the versatility and wide-ranging uses of hot melt adhesives in many industries. Our top adhesive manufacturers work with us to provide custom hot melt adhesive solutions to meet your needs.

Our range of high-quality adhesives is extensive: Metallocene, EVAs, PEs, Low Application Temperature, Polyamides, APAO, and Compostable Hot Melts.

Our hot melt adhesives are designed to provide exceptional performance and are widely used in various industries, such as packaging, automotive, and product assembly.

Still finding yourself stuck? Speak with our experts and find out how hot melt adhesives can enhance your business operations today.

Hot melt pressure sensitive adhesives (PSA)

Hot Melt Pressure Sensitive Adhesives are a unique category of adhesive tapes that provide aggressive and permanent tackiness at room temperature. With cohesive holding power and elastic nature, they firmly adhere to dissimilar surfaces with mere contact.

Hot melt PSAs require no water or solvent to exert a strong adhesive holding force on various substrates like paper, plastic, and metal. Unlike hot melt adhesives, they are much tackier at room temperature.

When it comes to hot melt pressure-sensitive adhesives, trust the experts at BC Adhesives to deliver the highest quality and most reliable solutions for your project.

Polyurethane adhesives (PUR)

Polyurethane (PUR) is a versatile adhesive solution that can be used for various applications. PUR adhesives are highly flexible, have excellent temperature resistance, and can bond to various coatings, such as UV coatings.

We offer several types of PUR adhesives including hot melt, liquid, 2-part liquid, and 2-part polyurea options.

Unlike traditional hot melt adhesives, PUR adhesives are significantly stronger due to their polymerization when exposed to air moisture. With fast set times for initial bonds and continued strength over time, it makes PUR adhesives ideal for manufacturing and assembly applications where water, vibration, and temperature resistance are critical. Other common uses for PUR’s are in RV, camper, and flooring assemblies.

Don’t get stuck searching for the right PUR adhesive for your next project, trust BC Adhesives’ expertise and custom solutions to save the day.

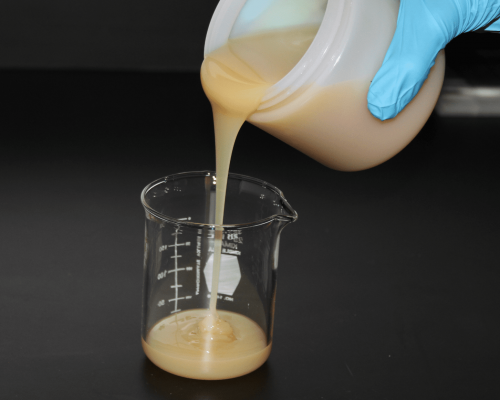

Water-based adhesives

Water-based adhesives are a type of adhesive solution technology that uses a combination of water, polymers, and additives to create a bond between two substrates. Unlike other types of adhesives, water-based adhesives are environmentally friendly and do not contain any volatile organic compounds (VOCs), making them safe for both people and the environment.

These adhesives work by evaporating or getting absorbed into the substrate, leaving behind a reliable and cost-effective bonding option with excellent adhesion to many challenging substrates.

Take the challenge out of finding the perfect adhesive, trust BC Adhesives’ advanced technologies and unwavering commitment to excellence to find you the best adhesive solution for your needs!

Let our experts help you find the perfect solution

Web adhesives

Web adhesives are hot melt adhesives formed into a weblike, non-woven material that handles like fabric. Below are some of the benefits to your manufacturing process of using web adhesives:

Increase Productivity

- Web adhesives are easy to use and apply, increasing productivity and shortening manufacturing time.

Save on Operational Costs

- Web adhesives save on energy and operational costs, allowing plant space to be more effectively utilized.

Simplify Processes

- Web adhesives are free from Volatile Organic Compounds, offering a low environmental impact, simplifying processes and providing safer adhesion options.

Instant-adhesives cyanoacrylates

Instant adhesives, also known as cyanoacrylates (CA), are fast-curing, one-part products that react with moisture to quickly reach handling strength within seconds. They are ideal for applications requiring high strength for a small bond area, tight-fitting joints, and rapid curing times.

Instant adhesives are available in different formulations, allowing them to bond to various materials such as metals, leather, paper, elastomers, engineered plastics, and some low surface energy (LSE) plastics.

No matter what industry you’re in, instant adhesives are reliable bonding solutions that deliver speed and strength when needed most. That’s why BC Adhesives partnered with the best! Bostik’s Born2Bond instant adhesives are the new generation of instant adhesives with all the advantages of its predecessor and none of the disadvantages. Discover the future of instant adhesives with BC Adhesives!

Butyl extrusion systems & tapes

Butyl extrusion systems and tapes are versatile adhesive solutions used in many applications. Butyl rubber is the perfect material for adhesives because of its malleability and impermeability to air and water. Its versatility and waterproof properties make it essential for many industries, including those requiring construction, synthetic turf installation, waterproofing piping, and pond and dam lining.

Consider butyl adhesive if you need an adhesive solution that can withstand water, air, and other environmental, and let BC Adhesives help you find the perfect solution!

epoxies

Our epoxy adhesives are highly versatile and extremely strong. They are two-part adhesives that form when you mix epoxy resin and hardener.

Epoxy adhesives can fill gaps; it can be sanded, drilled, and painted, which gives it a much wider range of uses than standard glue. In addition, high-temperature epoxy adhesives are advantageous, as they can adhere to a wide variety of materials while providing resistance to chemicals and other environmental factors. Epoxies can also offer excellent creep resistance under sustained loads, making them the most widely used structural adhesive.

Trust BC Adhesives’ team of expert technical specialists to help you choose the right Epoxy adhesive for your project. Our commitment to quality and innovation ensures your success.

Discover what our experts can offer so you can find the perfect solution

Methyl methacrylate adhesives (MMA)

Methyl Methacrylate (MMA) adhesives are a type of acrylic adhesive that have a unique formulation allowing them to cure rapidly at room temperature. This results in a full bond strength soon after application, making them highly resistant to shear, peel, and impact stress.

Compared to other structural adhesives, MMA adhesives do not require heat to cure, providing an added advantage. The flexibility of MMA adhesives makes them suitable for bonding panels of aluminum to other panels, composite bonding of truck trailer beds, bonding hulls, deck liners, ski boats, yachts, and internal fixtures.

The possible applications for Methyl Methacrylate adhesive may seem endless and overwhelming. With BC Adhesives’ unparalleled expertise and innovative solutions, we will work together to find the perfect adhesive so you can get the job done.

UV curing adhesives

Our high-quality UV-curing adhesives are a one-component, solvent-free adhesive containing 100% solids. UV adhesives are known for their ability to control their cure rate, which can be adjusted for each application. They also come in different viscosities, allowing for manual and automated dispensing of the adhesives.

UV Adhesives are used in various industries, including electronics, automotive, graphic arts, and industrial manufacturing. UV-curing adhesives are ideal for producing high-quality and durable graphics in the sign and display industry. They are also widely used for bonding and sealing plastics, metals, and glass in various industrial manufacturing processes.

Trust the experts at BC Adhesives to be your guiding light when choosing the proper UV-curing adhesive for your project!

Sealants & hybrid polymers

There are many grades of sealants and hybrid polymers, each with unique performance features. Choosing the right product for the job is essential; often, the best formula for the task at hand is the higher-grade solution. BC Adhesives’ innovation and expertly crafted adhesives provide only the highest quality sealants and hybrid polymers, delivering the desired results.

Sealants and hybrid polymer adhesives are crucial in various manufacturing and construction markets. With a wide range of applications, including creating air-tight buildings, blocking water and moisture, and filling gaps and cracks, these adhesives are essential tools for any builder or manufacturer. Thanks to their impressive versatility, they are capable of cross-link curing and can provide outstanding resistance to high and low temperatures.

The experts at BC Adhesives have a solution for any project. From large-scale construction jobs, to smaller manufacturing applications our high-quality sealants and hybrid polymer adhesives offer a reliable and effective solution for all your bonding needs.

Anaerobic adhesives threadlocker

Anaerobic adhesives are a powerful and versatile type of industrial adhesive that hardens in the absence of oxygen and the presence of metal ions, such as iron or copper, resulting in a robust and long-lasting bond.

Anaerobic adhesives are widely used for bonding metals, plastics, and other materials with exceptional strength and durability. Threadlocking is one of the most common applications of anaerobic adhesives, as they effectively prevent screws, bolts, and other threaded fasteners from loosening due to vibration or other stresses. Other applications include gaskets, retaining, and sealing, making anaerobic adhesives a highly effective bonding solution for various industrial applications.

Don’t let weak bonds throw a wrench in your industrial applications. Our reliable, high-quality anaerobic adhesives will keep things tight and running smoothly. Reach out to one of our experts to learn more!

Don’t waste time searching for the perfect adhesive! Let BC Adhesives take the guesswork out of bonding and provide a reliable and effective solution that will exceed your expectations.

At BC Adhesives, we pride ourselves on finding the perfect adhesive solution. No matter what sticky challenge you’re facing, we’re up to the task. Our experts work tirelessly together to deliver custom solutions that meet your unique needs. Whether you’re working on a small project or you are a large-scale manufacturer, we’ve got you covered.

Contact Us

Please fill out the form below, and we will reply within 1 business day.