Adhesive Services

Trust the experts at BC Adhesives for reliable, expert support in maintaining your equipment and optimizing your adhesive applications.

BC Adhesives - Adhesive Services

Consulting & Analysis Services: Enhance Your Adhesive Solutions

Experience the best adhesive services in the industry. The team at BC Adhesives uses our expertise in selecting the perfect product for your specific application. Our team is here to assist you in optimizing your project for cost, efficiency, consistency, and repeatability, regardless of the project phase.

Minimizing Manufacturing Slowdowns

Manufacturing slowdowns often result from issues with the product or machinery. Some adhesives may not work well with machines, causing blocked orifices and requiring cleaning, which pauses the production line. If the adhesive isn’t performing efficiently, costs may increase due to slower production or rework. With our support, we’ll help optimize the application equipment and process to improve line efficiencies and reduce downtime.

Monitoring and Optimization

We provide ongoing monitoring and optimization of your adhesive application process. By considering the cost per thousand pieces manufactured and the amount of adhesive used, we regularly check each quarter to ensure smooth operation and optimal adhesive usage. We can also assist with the assembly of new products by analyzing your current process and comparing alternative technologies or methods for better results.

Adhesive Bonding Benefits for Assembly Solutions

Adhesive bonding provides an impressive range of advantages for assembly solutions, including being more efficient, effective, and reliable when compared to traditional methods like bolts or other assembly techniques. With our combined expertise in manufacturing and equipment, we possess the unique ability to design and implement the optimal setup tailored to your specific needs.

Ready to get started on your next adhesives project? Contact us today, and one of our team members will be in touch within 1 business day to gather more information to get started.

BC Adhesives Data Analyzer

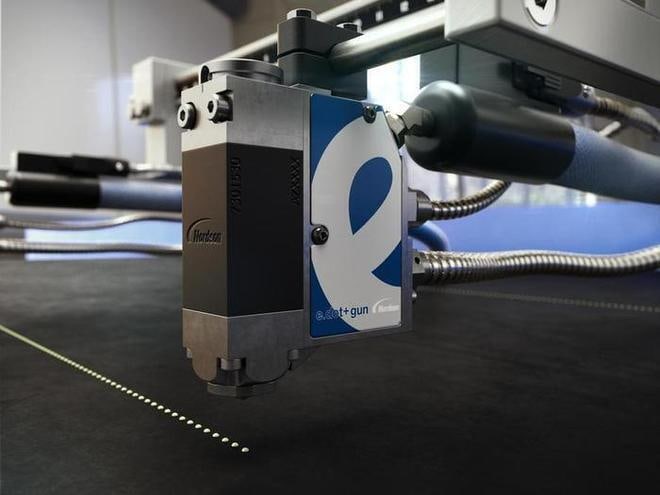

BC Adhesives offers innovative ATS Data Analyzer software, specially designed to be compatible with Nordson equipment, to provide precise adhesive usage tracking and reporting for manufacturing processes. The software works seamlessly with Nordson systems with the ATS tracker attachment or the ProBlue Liberty machine with an in-built tracker.

This advanced system is essential for optimizing the adhesive application, reducing waste, enhancing overall efficiency, and ensuring product quality. By monitoring adhesive usage in real-time, manufacturers can make informed decisions and adjustments to their adhesive application process, ultimately leading to significant cost savings and improved production outcomes.

- The ATS Data Analyzer software is specifically designed to be compatible with Nordson equipment, enabling accurate, real-time tracking of adhesive usage during the manufacturing process.

- Utilizing a user-friendly interface, the software generates easy-to-read graphs and reports that highlight adhesive over-application or under-application, which can help identify potential cost savings and areas for improved efficiency.

- BC Adhesives offers flexible reporting options, including 24-hour, bi-weekly, or quarterly reports, ensuring manufacturers can access the insights they need to optimize their adhesive usage.

- The software can be installed on internal team computers, empowering staff to monitor adhesive usage more closely and make data-driven decisions to enhance the manufacturing process.

Reach out to BC Adhesives to integrate this invaluable service with your existing Nordson systems, simplifying adhesive usage tracking and streamlining your manufacturing process for better results and cost savings.

The Best Adhesive Technical Services

To ensure the best adhesive services, we prioritize our customer’s satisfaction by offering preventative maintenance on equipment. Our in-house technicians are available for phone or in-person consultations at no additional cost as long as you’re using our products. This saves you from the expenses of involving an equipment manufacturer.

We are certified in several different product lines, including:

- Nordson HotMelt Tank Melters, Hoses, and Applicators

- Nordson HotMelt Drum and Pail Unloaders

- Nordson Cold Glue Piston and Diaphragm Systems

- Nordson Pattern Control and Runup Control

Nordson ATS (Adhesive Tracking System) Integration - and Data Collection

Our team at BC Adhesives includes several former Nordson technicians with extensive knowledge of hot melt and cold glue dispensing equipment.

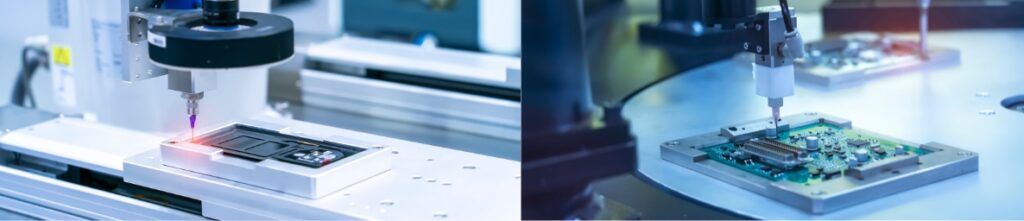

As a trusted third party, BC Adhesives frequently helps compare manufacturer equipment quotes, providing comprehensive support to our customers at every stage of applications. This support includes equipment consulting and installation, troubleshooting and repairs, application optimization, adhesive stitching, and glue reduction techniques.

Reach out to BC Adhesives to integrate this invaluable service with your existing Nordson systems, simplifying adhesive usage tracking and streamlining your manufacturing process for better results and cost savings.

BC Adhesives State Of The Art Testing

At BC Adhesives, we provide a wide range of testing and analysis services in our state-of-the-art lab. Our goal is to deliver the most reliable and accurate adhesive solutions for your projects, such as:

- Rate of Set

- Loop Tack

- Peel Adhesion

- Shear Resistance

- Adhesive Properties

- Heat Resistance

- QUV (Weathering)

- Instron Testing

- Competitive Analysis

- Tensile, Elongation, and Tear

- Rheology

- Viscosity

- Environmental Chamber Humidity

- Analytical Services

- Custom Testing

- Flex Testing

- Page Pull Strength

To ensure a perfect bond for your end product, we specialize in bonding various substrates to create the ideal end product. No matter the raw materials, we can find a solution to bond them effectively. We harness our expertise in selecting different chemistries from multiple suppliers to achieve the best possible outcome for your project.

Get in touch with us today to learn more about our services.

Contact Us

Please fill out the form below, and we will reply within 1 business day.