Consultation Services

Upgrade your workflow

BC Adhesives offers unparalleled support on equipment, process, and manufacturing needs at no cost to our customers, saving them valuable time, materials, and money.

Upon request, our specialists perform monthly, bi-monthly or quarterly audits on manufacturing lines to ensure they are running as efficiently as possible. Besides checking the lines, we also check Nordson / Graco glue tanks to ensure there aren’t any issues that could cause pop-opens, plugged nozzles, stringing, or other issues. During every audit we analyze the amount of glue being applied to the parts or products and pull flaps off the line to check for signs of fiber tear. In addition to that, we also weigh the glue to determine that customers are using the correct gram weights.

Experts at assembly line optimization

Many operators believe that the more glue used the better, but this is rarely the case. Our experts carefully adjust system settings to ensure optimal performance on all equipment, and we even walk customers through the process so they have a full understanding of any changes that are made.

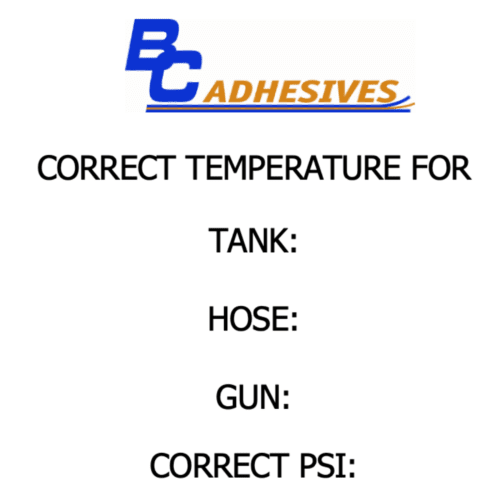

We use laminated hang tags on equipment that details optimal temperatures and pressures for each part of the machinery. Because each glue runs at different temperatures and pressures, we offer recommendations and settings that allow operators to keep machinery running consistently. Contact us today to optimize your workflow.

Tech swap – Simplifying your processes

When it comes to adhesives, product prices are constantly changing. BC Adhesives can perform a tech swap for customers by finding more cost-effective alternatives for your application without sacrificing product quality or performance.

Consultation on Nordson data analyzer

Industry-specific advisement

Product assembly

BC Adhesives receives substrates from customers that are to be glued together to be examined in our lab. Once glued and cured, our team runs a series of adhesion tests specific to each customer’s needs. Some tests included putting the assembled parts in industrial ovens for temperature tests and freezers for cold tests. We then compile a detailed lab report so the customer knows exactly where their product stands in terms of durability. Contact us today to learn more.

Graphic arts

BC Adhesives offers a variety of tests to rate the stress quality of book adhesives, from flex tests to page pull tests. We then compile a full report that illustrates any inconsistencies or optimization opportunities. Contact us today to schedule a graphic arts stress test.

Labeling

Bottle labels need to undergo several tests to determine the quality of the adhesive on the bottle. BC Adhesives offers cooler tests to ensure temperature doesn’t cause any label bubbling or peeling, and water tests to determine how long before a label will begin breaking down when submerged in water (or a cooler of melted ice, for example). Contact us today to schedule a labeling test.

Packaging

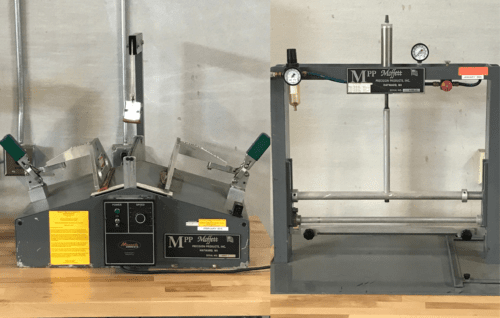

BC Adhesives can help customers adapt a hot melt stitching system, which allows an automated adhesive gun to dispense beads of adhesive onto a box flap as opposed to a line. This continuously saves adhesive and money for the customer. Contact us today to learn more about converting to hot melt stitching.Several years ago, Rebecca Reker from BC Adhesives changed the game on all the adhesive we use. They worked on our schedule, worked with our operators and found us better products for our everyday operations. Not only a better product but saving us money as well. They have a well-educated staff that is fun to work with. Highly Recommended.

– Verified Customer