At BC Adhesives, we supply a variety of labeling adhesives ranging from water-based / cold glue and hot melt adhesive products specially formulated for use with glass, PET, HDPE, and metal. Our water-based / cold glue labeling adhesives feature easy cleanup and efficient application rates with customers generally seeing a large decrease in their consumption. On the flip slide, our hot melt adhesives offer the freedom to choose between swirl spray and direct contact application, using either magazine or roll fed label stock. Save time on cleanup, keep your pots char free, and clean up the stringing with our premium competitively priced formulations.

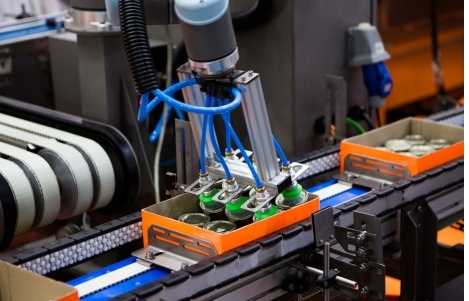

We offer many high performance tray sealing adhesives that are capable of adhering a wide range of substrates. They are the trusted choice by many manufacturers for securely sealing your packaged products. Designed to meet the demands of various industries, our tray sealing adhesives are engineered for exceptional performance and reliability. Our formulations are specially formulated to create a strong and hermetic seal between the tray and its cover film. Whether you’re packaging food items, pharmaceuticals, or other perishable goods, our tray sealing adhesives ensure that your products remain protected from external contaminants and maintain their quality.

Whether you are labeling a bottle that is already filled or empty, BC has an adhesive that can handle either type of application. The unique formula allows for labels to expand and contract due to carbonation and will not create “dog ears” due to be stored in extremely warm climates or warehouses. Some of our formulas offer one of the highest softening points for this purpose.

Beer bottle labels require a special variety of adhesive. Labels must be water-resistant and able to stand up to a considerable amount of condensation. BC Adhesives offers a creative range of beer bottle labels to ensure customers can bring their design and branding ideas to life:

BC Adhesives products never dry out on pallets, transfer drums, or fingers. They’re meant for use in the fast-paced and demanding environments that many of our industrial clients work in every day.

Exceptional adhesion:

Our canning labeling adhesives are engineered to deliver superior adhesion to a variety of canning materials, including metal, glass, and plastic. This ensures that your labels stay in place, even in challenging environments such as cold storage or high humidity.

Versatility:

Whether you’re canning fruits, vegetables, preserves, or other products, our range of adhesive solutions are formulated to work seamlessly with your different material and container surfaces.

FDA Compliant:

Food safety is our top priority. Our adhesives are formulated to meet FDA regulations and industry standards, making them safe for direct contact with food products. You can trust that your labels will maintain their integrity and adhere securely to your canned goods.

Cost Efficiency:

Our diverse portfolio of labeling adhesives are not only reliable but also cost-effective. By reducing label application errors and label waste, our adhesives help streamline your canning production process, ultimately saving you time and money.

Expert Guidance:

Our experienced team is here to assist you in finding the ideal adhesive solution for your canning labeling requirements. We provide technical support, offer guidance, and can recommend the right adhesive based on your specific needs.

Coated glass bottles require specialized adhesives to ensure labels remain firmly attached. At BC Adhesives, we’ve developed a proprietary adhesive solution for coated glass bottles. This ice-proof adhesive remains firmly attached to glass bottles when exposed to condensation. Need labeling adhesive for coated glass bottles? Contact us!

At BC Adhesives, we develop adhesive products capable of exceeding the stringent demands of a broad spectrum of application environments. We develop our products with affordability and efficient consumption in mind. Our dedicated staff and familiarity with advanced technology ensure that our customers always receive the optimal adhesive solution for their use case.

For more information about BC Adhesives and our adhesive and labeling solutions, please contact us.

We have been a BC Adhesives customer since 2013. In that time we have had changes to both amount and type of glue we use. BC Adhesives has gone above and beyond, time and time again, to make sure we had the correct type of glue and that we never ran out—even when it was due to our ordering mistakes. For me, Jon Hansen and the team at BC Adhesives are a pleasure to work with and do an outstanding job.

– Satisfied Customer

BC was asked to come in and audit a well-known craft brewers lines for potential improvement. This craft brewer had been using their adhesive products for the last 10+ years and were interested in finding new technologies on the market.

BC’s team of labeling experts were able to find several areas for improving their process before introducing new technologies. The first was moving the air knives closer to the labeling application. This allows the labels to hit the bottle with as clean as a surface as possible. Right off the bat the label swimming the prospect was experiencing was taken care of. Next we noticed the amount of slinging that was happening because of the speeds the lines were running at. The operators had also told us that cleanup is a pain every shift.

Part of our jobs as the expert is knowing the latest and greatest technologies. There are new products that have drastically reduced slinging on high speed lines which directly reduces cleanup time. In this case we were able to cut their cleanup time in half. This allowed the operators to spend time working on other parts of the lines that they normally wouldn’t have time to do in a normal shift.

After working with numerous of the country’s largest craft breweries, our team has developed an understanding of best practices for the entire packaging process. There are several things that can be done upstream to help make the labeling process much easier and cleaner. Call your local rep to have your line audited today.