Industries Served

A trusted leader in adhesive solutions

BC Adhesives is a leading supplier of hot melts, PUR, liquid adhesive, caulks, sealants, butyl, instant adhesive, epoxy, MMA, uv curing adhesive, and anaerobic adhesives for any market. With decades of experience we work with our customers to shorten cycle times and optimize manufacturing processes.

A diverse landscape of adhesive solutions

With more than two decades of experience our trusted team can help you optimize your workflow.

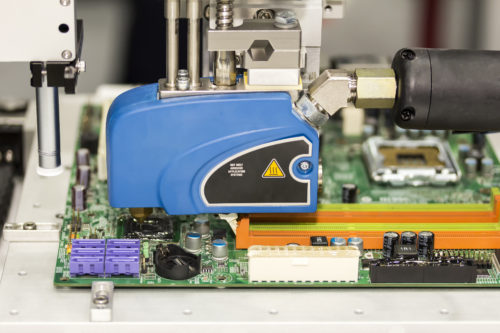

Adhesives for product assembly

Our adhesives for product assembly are designed to deliver exceptional bonding performance, ensuring the durability and reliability of your assembled products. With our custom formulated adhesives, you can achieve strong and secure bonds between various materials, whether it’s metal, plastic, wood, fiberglass, composites, etc.

These versatile adhesives streamline the assembly process, allowing for efficient production and increased productivity. They offer excellent adhesion properties, creating reliable bonds that withstand the rigors of everyday use.

A few applications we excel in include woodworking, kitchen cabinetry, air filter assembly, and laminating to almost any substrate. Our lineup of adhesives have very high green strength, strong initial tack for immediate handling, excellent temperature, moisture, flexibility after curing, and aging resistance.

Adhesives for graphic arts

There are many adhesive applications for the publishing industry. A few that we specialize in are PUR binding, perfect binding, layflat binding, case binding, case making, and many more. To learn more about our adhesive solutions for publishing, click the button below:

Adhesives for mattress assembly

We have a variety of adhesives for mattress assembly. Our hot melt PSA’s and APAO’s are what we commonly lead with, but we do have EVAs as well. Our technologies for assembly ensure strong bonds between components, streamlining production, and enhancing mattress performance. Our formulations are also versatile, eco-friendly, and easy to apply. They deliver a clean finish and optimal durability. Elevate your mattresses with our high-quality adhesives.

Adhesives for labeling

Labeling adhesives can be broken into two basic types― water base adhesives and hot-melt adhesives, although other adhesives may be used in specialty applications. Some of the common adhesives we use are formulated for glass, PET, and HDPE. They offer coated glass improved machinability, doesn’t dry out, easy to clean up, swirl spray or direct contact, and many more. Click the button below to learn more about or labeling adhesive solutions:

Adhesives for packaging

BC Adhesives has a complete line of adhesive products for the packaging market. Some of their most popular packaging adhesives work well with refrigeration and freezer grade cases and cartons. They also have many solutions for canning (veggies, pet food, chicken, sauce, salsa, paint, etc…). In addition to that, their hot fill products (molten sauce, cream cheese, etc…) work extremley well for cases and cartons, trays, and many more. The BC Adhesives team continually works to ensure their packaging adhesive products evolve alongside this changing market. As stated previously, their adhesives are designed to handle a wide range of end-use temperatures and adhere to a variety of substrates, rigid packaging applications include freezer, general purpose, low application temperature and specialty.

To learn more about our adhesive solutions for packaging, click the button below:

How we help choose the best adhesive for your application

Are you looking for an adhesive solution for your current or future application? A few common questions we would ask to start our evaluation process include:

- What are the raw materials that I need to bond together (steel, plastic, cloth, corrugate, coated corrugate, etc.)?

- What type of application equipment is currently used?

- What ambient temperature range will your product be used in?

- What is the minimum cure time?

- What is the cycle time if automated?

- Is flexibility important?

- What are the shortcomings of the current product?

- What is your product testing program?

- What are the testing parameters?

Several years ago, Rebecca Reker from BC Adhesives changed the game on all the adhesive we use. They worked on our schedule, worked with our operators and found us better products for our everyday operations. Not only a better product but saving us money as well. They have a well-educated staff that is fun to work with. Highly Recommended.

– Verified Customer