BC Adhesives - Mattress Assembly Adhesives

Discover the advantages of hot melt adhesives for mattress assembly. Learn the benefits and application methods commonly used for efficiency. Our foam attachment chemistries are also made with over 55% bio-based raw materials to help your end product be more environmentally friendly. Besides the formula characteristics their versatility shines in various mattress assembly applications, including foam-to-foam, foam-to-textile, textile-to-textile, and coil-to-textile bonding. Upgrade your mattress manufacturing process with the power of BC Adhesives

Hot melt PSA used for mattress assembly

Hot melt pressure-sensitive adhesives (PSAs) are widely used in mattress assembly for their exceptional bonding properties and numerous benefits. These adhesives offer a convenient and efficient solution for securely bonding different mattress components together.

Benefits of BC Adhesives hot melt PSA’s:

Strong and Durable Bonds: Hot melt PSAs create strong and durable bonds, ensuring that the mattress components remain securely attached even under constant use and pressure.

Improved Product Performance: By effectively bonding different layers of the mattress, hot melt PSAs enhance the overall performance and durability of the finished product. They contribute to better stability, reduced noise, and increased structural integrity.

Clean and Eco-Friendly: Hot melt PSAs are solvent-free and have low VOC emissions, making them environmentally friendly and safe for both manufacturers and end-users. They do not emit harmful odors or release harmful substances into the environment.

Ease of Use: Hot melt PSAs are user-friendly and easy to apply. They can be used in various application methods such as beads, swirls, spray, or roller, allowing manufacturers to choose the most suitable technique for their specific production setup.

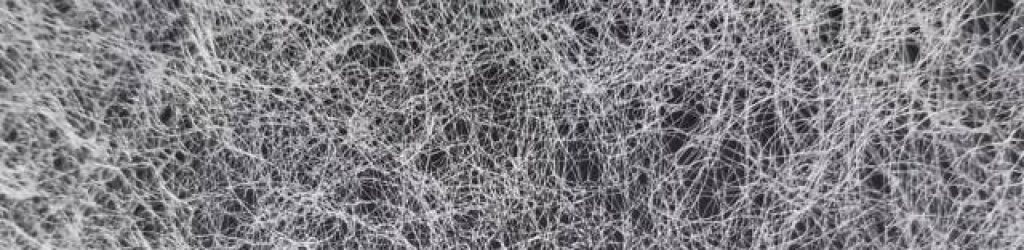

Web adhesives, hot melt adhesives converted into a non-woven fabric-like material, are made from polyamide, polyester, polyolefine, and polyurethane polymers. These adhesives can be produced using modified melt-blown processes for standard web adhesives or modified blown film processes. With a rough surface and fine fibers, web adhesives bond effectively to various substrates, resulting in a strong and durable bond. Web adhesives are activated by heat, pressure, or a combination.

These environmentally friendly adhesives offer numerous advantages over other bonding options, including breathability, customization options, reduced material waste, simplified application, and a good bond-to-porosity ratio. Being 100% solids, web adhesives contribute to less pollution and waste, making them a more sustainable choice. Additionally, they are free from harmful chemicals and do not require special equipment or ventilation during application, which reduces energy consumption and minimizes potential hazards.

Web adhesives are compatible with various substrates, such as wood, leather, urethane foam, fabric, metals, PVC, ABS, aluminum, fiberglass, and treated PP. Selecting the right web adhesive involves considering factors like melting temperatures, softening point, viscosity, solvent, water resistance, basis weight, and fire retardancy must be considered. Activation temperatures typically range from 170°F to 330°F, and fire retardant web adhesives are available for applications requiring fire retardancy as a performance feature.

APAO’s used for mattress assembly

BC Adhesives APAO polymer adhesives, utilize exclusive catalyst and production processes. This unique approach allows for customization of APAO polymers by incorporating additional hot melt adhesive components such as plasticizers, tackifiers, or waxes. Tailoring the formulation enables you to achieve the precise features required for your specific application.

Benefits of BC Adhesives APAO’s:

- Boost productivity: Faster line speeds and increased efficiency translate to greater productivity.

- Enhanced adhesive performance: BC Adhesives APAOs deliver a solid and dependable bond, reducing the risk of improper adhesion.

- Superior cohesion and thermal stability: Outperform other hot melt systems in terms of bonding strength and stability.

- Consumer-friendly and eco-conscious: Very low VOCs, no odor, and reduced off-gassing make mattresses more appealing and environmentally friendly.

- Quick assembly: Nearly instant initial tack enables speedy assembly and timely product delivery.

- Long-lasting durability: The durable bond ensures your products withstand years of typical mattress usage, often outlasting the tear strength of foam or fabric.

Let us help - Contact us today

Contact us today to learn more about the various hot melt adhesives you should be implementing into your mattresses! With more than two decades of experience, our trusted team can help you optimize your workflow and work towards a healthier planet.

Applications for mattress assembly

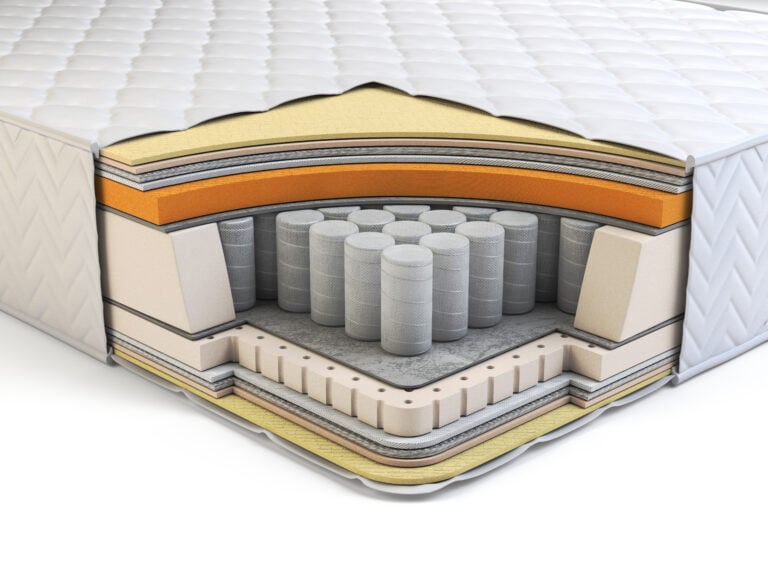

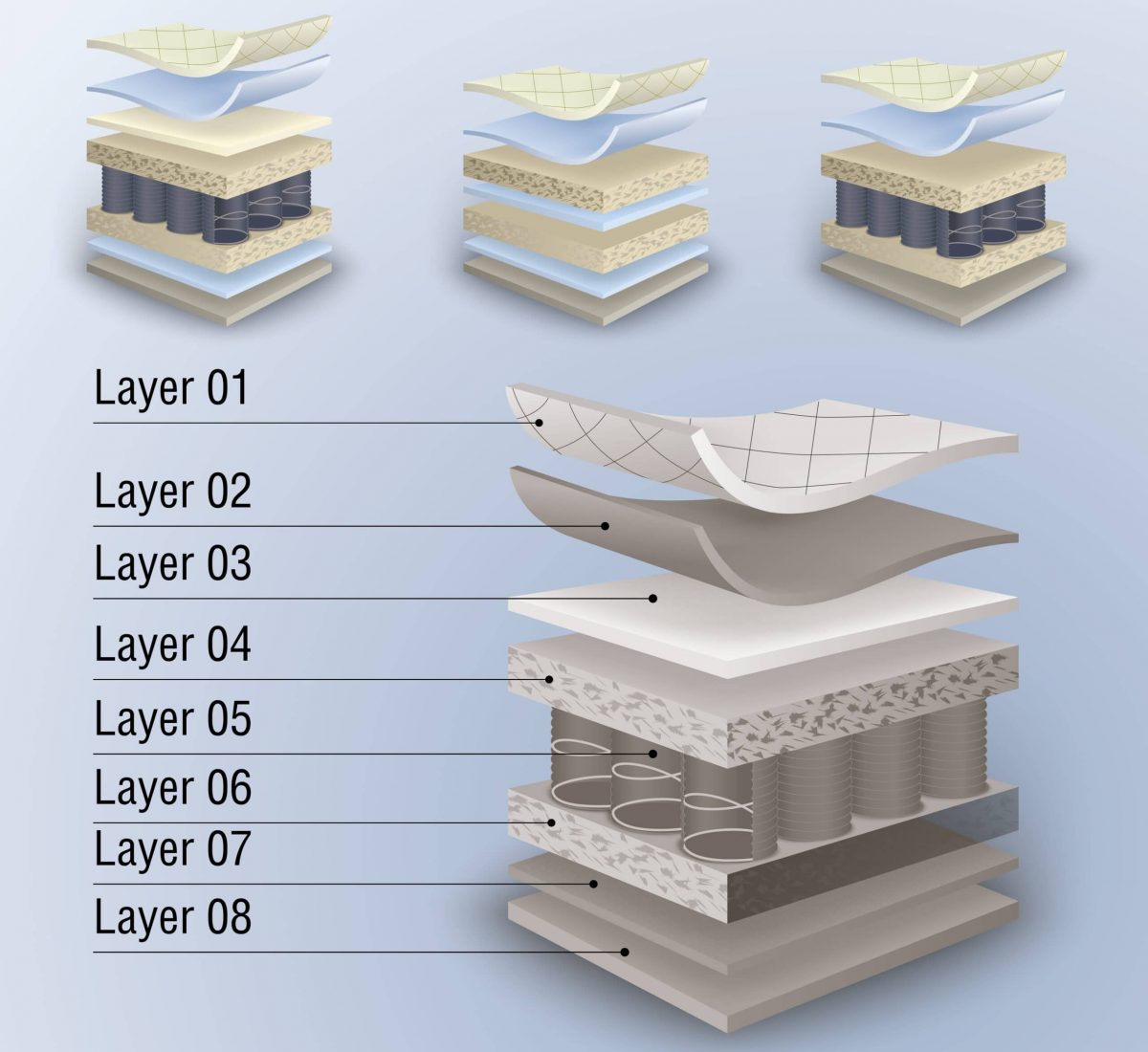

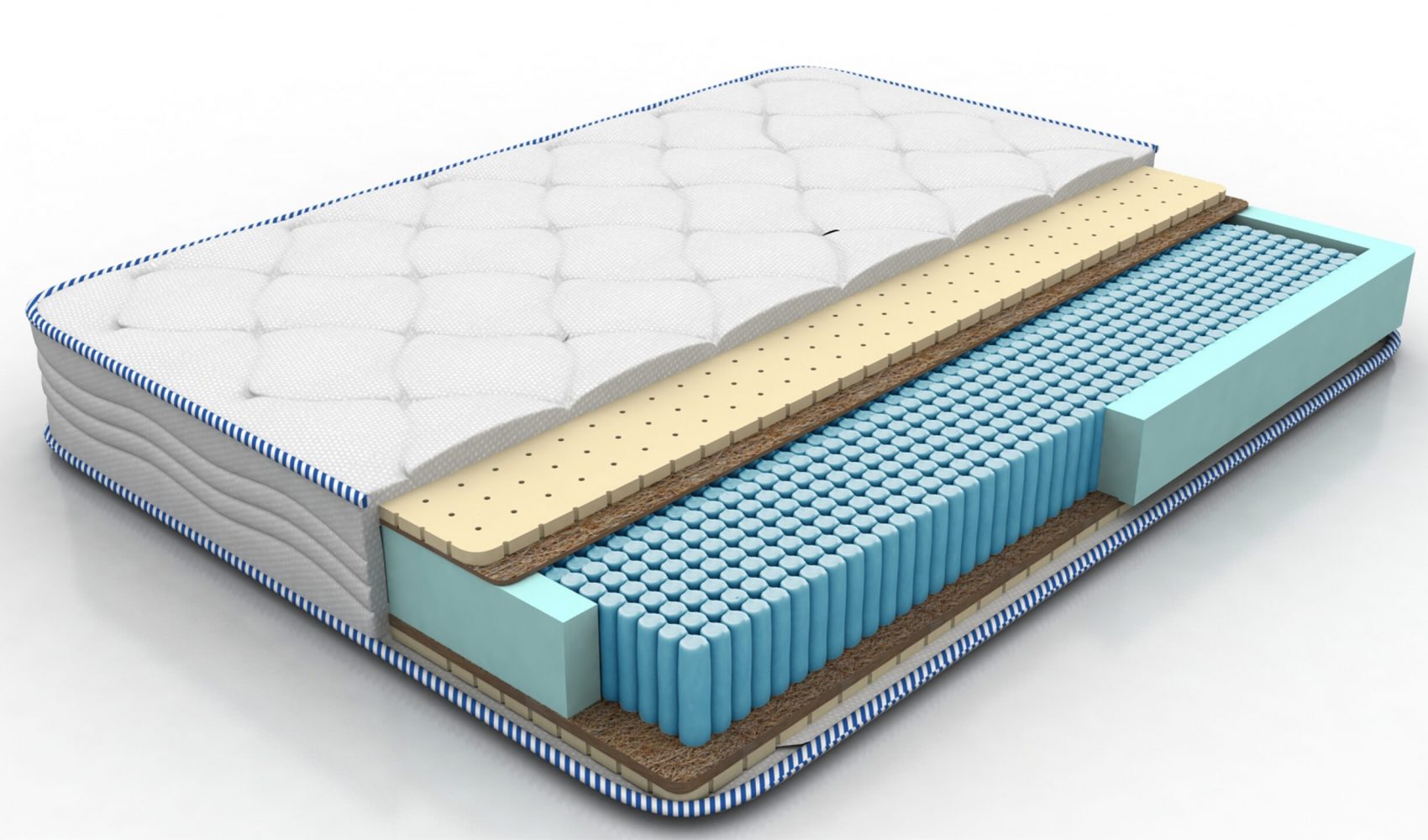

Foam Bonding: Hot melt adhesives are widely used to bond foam layers together, creating a stable and supportive mattress core.

Fabric Lamination: Web adhesives provide effective bonding for attaching fabric panels, ticking, or covers to foam or spring components, ensuring a seamless and neat appearance.

Edge Closings: Hot melt adhesives are utilized to securely close the edges of mattresses, ensuring a tight and clean finish.

Component Attachment: They are employed for attaching various components such as labels, handles, and trims to the mattress, adding functional and aesthetic value.

Understanding the characteristics for each hot melt adhesive as it relates to your application

Melt Viscosity (MV): Measuring the fluidity of the polymer at a specific temperature (usually 190°C/375°F), MV is expressed in centipoise (cps). Lower viscosity allows for efficient spray applications, which are increasingly common in the industry.

- Substrates:

The choice of substrates plays a crucial role in determining the right hot melt adhesive for your application. The compatibility and interaction between the adhesive and the substrates directly impact the overall performance and durability of the bond. It is vital to consider the characteristics of the substrates to ensure proper adhesion and long-lasting results.

Factors such as the material composition, surface texture, porosity, and flexibility of the substrates influence the adhesive selection process. Different substrates, such as foams, fabrics, plastics, and metals, have unique properties that require specific adhesive formulations to achieve optimal bonding.

By understanding the substrates’ properties and requirements, you can choose a hot melt adhesive with the appropriate adhesion strength, viscosity, and flexibility to ensure a reliable and durable bond. Conducting compatibility tests and consulting with BC Adhesives can help in providing valuable insights in selecting the right adhesive for your specific substrates and application.

Ring and Ball Softening Point (RBSP): RBSP indicates the heat resistance of the hot melt adhesive. It determines the temperature at which the material becomes soft enough to work with. It is crucial to select a softening point that safeguards foams and fabrics from damage or fire hazards.

Density: The density measurement determines the polymer’s hardness and provides insight into the strength of the cured bond.

Open Time: Open time signifies the duration during which the adhesive remains sticky after the curing process begins. Mattress hot melt adhesives can offer open times ranging from 10 seconds to 4 minutes.

Considering these specifications will guide you in choosing the optimal hot melt adhesive that aligns with your mattress manufacturing requirements and ensures excellent performance and durability. Contact the team at BC Adhesives for additional help.

Hot melt adhesives are a reliable and adaptable choice for various industries, substrates, and applications, as they deliver a robust and crackless bond. With their ability to withstand different environments they are well-suited for assembly projects that demand a long-lasting and durable adhesive solution.

Trust our experts to help you identify the ideal hot melt adhesive to meet your specific requirements and achieve success in your projects.

How to apply hot melt adhesives for mattress assembly

The mattress production process encompasses diverse bonding requirements and materials. In the mattress industry, adhesives play a crucial role in bonding foam-to-foam, foam-to-ticking, and non-woven materials to pocket springs. To accommodate these needs, hot melt adhesives are commonly applied using four methods:

- Beads

- Swirl

- Spray

- Roller

Each application method offers distinct advantages and suitability for specific bonding scenarios. Manufacturers carefully select the appropriate application technique based on the desired bond strength, production efficiency, and overall quality requirements. Understanding these different application methods empowers mattress producers to make informed decisions when choosing the most suitable adhesive bonding process for their specific needs.

Advantages of hot melt adhesives for mattress assembly

- Superior adhesion properties for reliable bonding

- Clean and efficient processing

- Low odor formulation for a pleasant working environment

- Exceptional thermal stability for consistent performance

- High flexibility in bonded materials during roll/unroll applications

Hot melt adhesives are a versatile, environmentally friendly, and efficient bonding solution for many substrates and applications as it relates to the assembly of a mattress. By considering factors such as melting temperatures, softening point, viscosity, basis weight, open time, etc. you can find the ideal hot melt adhesive to meet your specific needs. To ensure the best possible results, evaluating the performance of the selected hot melt adhesive in your application is crucial. If you need help finding the perfect hot melt adhesive for your project, the experts at BC Adhesives are ready to assist you. With their extensive knowledge and experience, they can guide you through the selection process and provide tailored recommendations to ensure optimal performance and satisfaction for your application.

Contact Us

Please fill out the form below, and we will reply within 1 business day.