What Adhesives Should I be Using For Assembly Applications?

Before we jump into this. You may be thinking. What adhesives should I be using for assembly? It’s is a common question we hear that’s a little complex to answer without knowing more about your application. However, below are some different options that work best for assembly. We highly recommend you fill out a Contact Form before you make your decision. Our team has well over 100+ years of experience with both adhesives and equipment, and are happy to schedule a call to discuss options that would best suit your application.

Some options include:

• Mechanical (bolts, screws, tabs, rivets, crimps, pegs, nails) (These often look ugly, can rust, squeak, and even be more expensive)

• Heat (weld, braze, solder)

• Joint Design (dove tail, mortise, tenon)

• Adhere (adhesive, tape)

Why Choose An Adhesive over nuts and bolts?

• Permits joining of materials with dissimilar coefficients of expansion and contraction

• Allows components to be designed with an “invisible” means of attachment

Key Performance Factors

• Adhesion: Measure of bond strength between an adhesive and a substrate.

• Tack: The initial attraction or grab of an adhesive to a substrate.

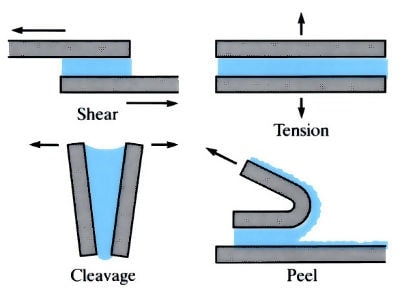

• Shear: The internal or cohesive strength of an adhesive film.

Pressure-Sensitive Adhesives Advantages:

• Minimal capital costs to apply on substrates

• Provides 100% coverage for optimal adhesion to bonding area

• Can improve aesthetics by eliminating visible mechanical fasteners

• Provides structural strength that can replace bolts, rivets, welds and other mechanical fasteners

• Permits use of lighter, thinner materials

• Bond dissimilar materials without incompatibility concerns

• Acts as moisture seal/environmental barrier

• Provides uniform thickness, gap-filling properties

• Shortens assembly time and boosts productivity (eliminates the need for bonding “both” substrates together at the same time and location providing optimum manufacturing flexibility)

• Eliminates need for surface refinishing to remove weld distortions, etc.

• Provides properties and functionalities beyond joining: sound/vibration damping, thermal conductivity, anti-friction/abrasion resistance, flame retardancy

Still unsure of where to begin with your assembly adhesive needs?

Check out BC Adhesives today to learn more about what adhesives you should be using for your assembly applications. BC Adhesives offers a wide range of adhesive solutions, and has a team of industry experts with a combined 100+ years of experience who are more than willing to visit your facility and take a look at what issues you may be having.

Stay up to date with us on LinkedIn