Things You Should Know About Water Based Adhesives

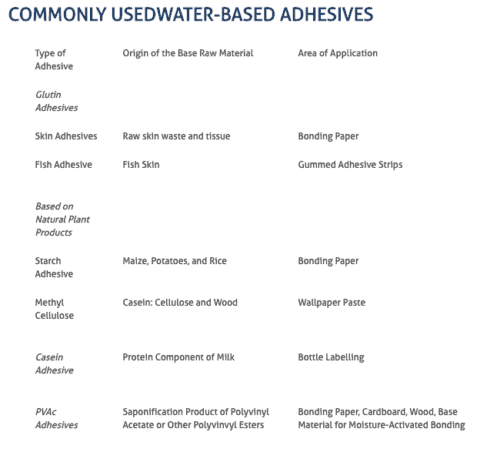

There are many scenarios where you should be using be using water-based adhesive. However, with everything there are pros and cons. The first thing to note is that Water-based adhesives can either be natural polymers meaning they are from plant-based sources such as (dextrins, starches), protein based sources (casein, blood, fish, soybean, milk albumen), or even animal based sources (hides, or bones). Water-based adhesives can also be from soluble polymers which include polyvinyl alcohol, cellulose ethers, methylcellulose, carboxymethylcellulose, and polyvinylpyrrolidone.

As previously stated, water-based adhesives can be used for a wide range of industries. Back in the day water-based adhesives were the only option to choose from until hot melt adhesives came along. Hot melts are more common now, but water-based still work for a variety of applications and industries. For example, in the bookbinding and graphic arts industries, water-based adhesives are great for keeping the consistency. The manufacturers we work with are providing us solutions that are very durable, temperature and moisture resistant and have a strong adhesion to an abundance of different substrates.

BC Adhesives has a comprehensive product portfolio formulated to exceed industry standards on specific paper stocks, films and bookcase materials. Beginning with the adhesive and continuing through the technical support and new product development. BC Adhesives we offers:

- Packaging options for all melt-on-demand systems with focus on digital

- Free Page pulls and flex tests

- Excellent aging stability

- Resistant to most inks and solvents reducing glue line failures

Overall, as a company we focus on bottom-line savings, while optimizing adhesive performance.

Water-Based Adhesives For Hardcover and Softcover Books

How books are made and consumed by people have changed over the years. It started with large runs on a single item and have now moved to small-scale production of many different printed material. The products we provide our customers our crafted to provide clean running products that have no stringing and good lay flat. Our products form a durable adhesive bond on both standard and digitally-printed paper. They also overcome potential adhesion issues resulting from the use of fusing oils and coatings. Our technical specialists work within the graphic arts industry researching and developing new products to achieve optimum performance.

Water-Based Adhesives For The Food And Beverage Markets:

As stated in a previous blog post, consumers are looking for better and more eye catching food packaging. New brands pop up all of the time, and consumers are always looking for new options. As consumers search the shelves for products often times the packaging implements whether they buy the product or not. Overall, consumers want functionality and convenience factors when it comes to packaging. Some key traits that customers and companies are looking for are sustainable solutions and food safety packaging. BC Adhesives Understands how these regulations extend to adhesives, sealants and functional coatings. Our manufacturers are choosing solutions to protect quality and assure safety to achieve high performance and maximize value of their products.

Navigating these packaging needs, manufacturers are partnering with suppliers who deliver solutions to support their consumer-centric agenda. BC Adhesives, sealants and functional coatings play a key role in beverage and container labeling, end-of-line packaging and metal packaging.

Product Assembly (Furniture Building Processes)

Screws and nails are methods of the past, and water-based adhesives can help produce lighter products, structures, and even improve quality, efficiency and sustainability for your furniture and building components. BC Adhesives supports a variety of wooden parts in many applications in the furniture industry. The team is a top solutions provider to the assembly industry and keeps its customers in mind when making decisions ensuring a true partnership.

Why Use Water-Based Adhesives:

Many industries and applications can benefit from water-based adhesives. Packaging, bookbinding, labeling, and woodworking are common places where water-based adhesives could be used. However, when deciding whether to use a water-based adhesive over a hot-melt we suggest reaching out to and industry leader in the adhesive space, BC Adhesives. The team has been in the industry since inception, and will become a great partner to your organization. The team will walk you through the benefits and drawbacks to water-based adhesives and help you make the decision based off your application. When working with assembly applications water-based adhesives serve an important role especially in woodworking and furniture products. They also work well with the graphic arts industry. Some pros to water-based adhesives are its ability to set quickly and form strong bonds that, unless exposed directly to excess water or moisture, will remain strong for an extended period of time. To find out if water-based adhesives are right for your application reach out to BC Adhesives.