Benefits Of PUR Adhesives

There are many benefits to using PUR Adhesives which we will indicate below. We will give you a deep dive of the benefits, what PUR adhesives are, why you should use them, the adhesion, the advantages of PUR ambient range and flexibility, the advantages of PUR adhesive extrusion systems, and the disadvantages of extrusion/nozzle systems. For more information or if you’re still confused please feel free to Contact Us today!

- PUR adhesives have excellent page pulls and flex values

- It bonds to coated and cross-grained stock

- Exceptional aging stability

- Impervious to print ink oil migration

- High cold and heat resistance

- Excellent lay-flat performance

- No limitation to book thickness

- Very thin application required 10-12mls vs. 25-30 mil per EVA

We’ll Explain What A PUR Adhesive Is?

- Polyurethane reactive is what it stands for

- PUR adhesives must be heated to become free flowing, like a conventional hotmelt

- The initial bond is formed as it cools and solidifies, like a conventional hotmelt

- Unlike conventional hotmelts, PUR has reactive components (Isocynate groups) which cure in the presence of humidity to form a strong elastomeric film.

- To learn more about PUR and what applications it’s best used for, click PUR APPLICATIONS

You May Ask, Why Our PUR?

- Our PUR works well with recycled papers which have shorter fibers which are difficult to bond

- The amount of paper fibers are being reduced

- Multiple coatings to build paper thickness and improve print graphics

- Residual print oils can attack traditional binding adhesives

- Peace of mind for the trade binder

A Few Adhesion Outcomes:

- First of all, it will bond to glossy, coated papers and some films

- Extremely high page pull values – paper failure

- Extremely high flex test values 1,000+ flexes

A Few Advantages of PUR Ambient Range and Flexibility Include:

- PUR adhesives have a typical heat resistance of 350F peel failure versus 165-200F for quality EVA

- Typical cold crack measured at -20F versus 30F for quality EVA

- Excellent flexibility/layflat characteristics

- Comparable to true Otabind if applied properly

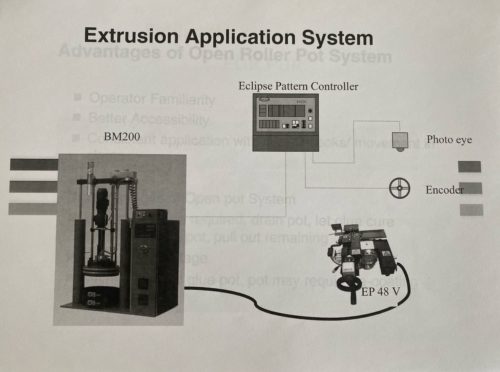

A Few Advantages of PUR Extrusion System Include:

- Easier clean up, wipe grease on slot, close slot at end of shift

- Less glue spoilage

- Precise glue cutoff, less glue buildup on three-knife blades

A Few Disadvantages Of Extrusion/Nozzle Systems Include:

- Slightly more complicated

- Requires some maintenance, valve replacement

- Less visibility

Stay up to date with us on LinkedIn